Basic Info.

Model NO.

Composite Fiberglass

Color

White

Advantage

Anti UV, Anti Aging, to Solve The Problem of Aging

Transport Package

Packing with Pallet

Specification

100g-600g

Trademark

Tianming

Origin

China

HS Code

7019

Production Capacity

3000tmonth

Product Description

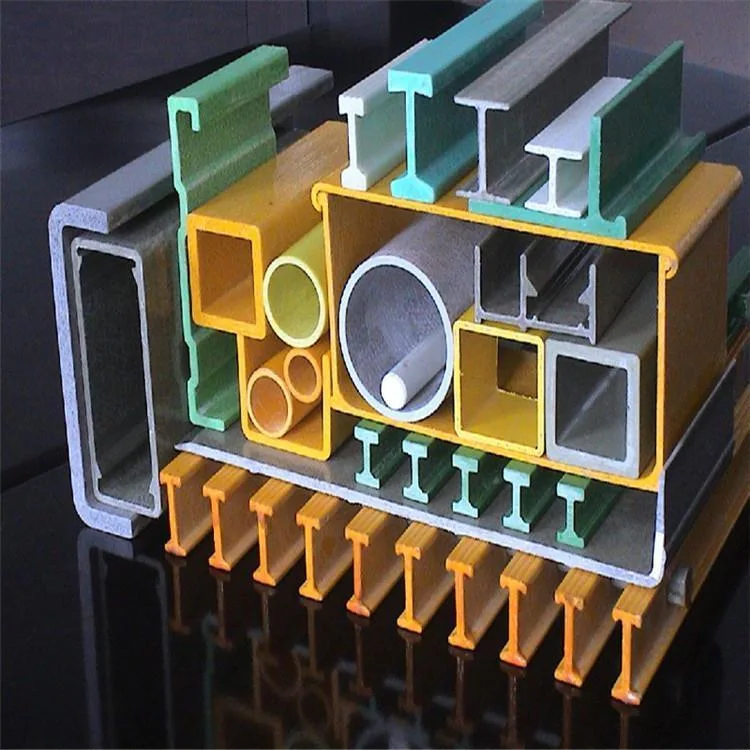

Fiberglass Chopped Strand Mat &Composite Mat

E glass / C glass Fiberglass Chopped Strand Mat for FRP products, Boat Building, Auto Parts

Chopped strand mat (or CSM as it is often known) is the most widely used of all composite reinforcement materials.Short strands of glass are randomly scattered and bound to create a mat which can then be wetted out with resin and used as a general purpose reinforcement for traditional fibreglass (GRP/FRP) moulds or parts.

Technical chat

Chopped Strand Mat technical chat

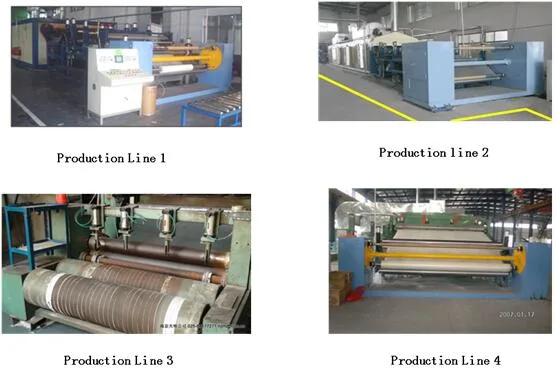

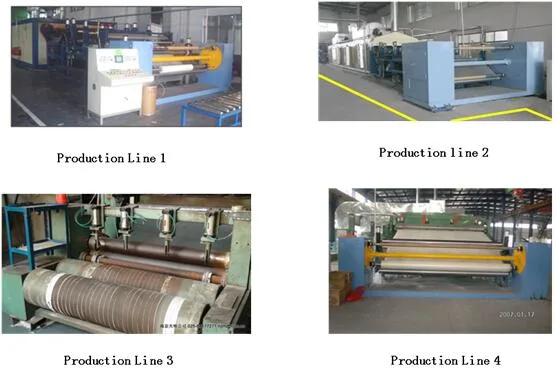

Production Line

Four different production line for kinds of Fiberglass

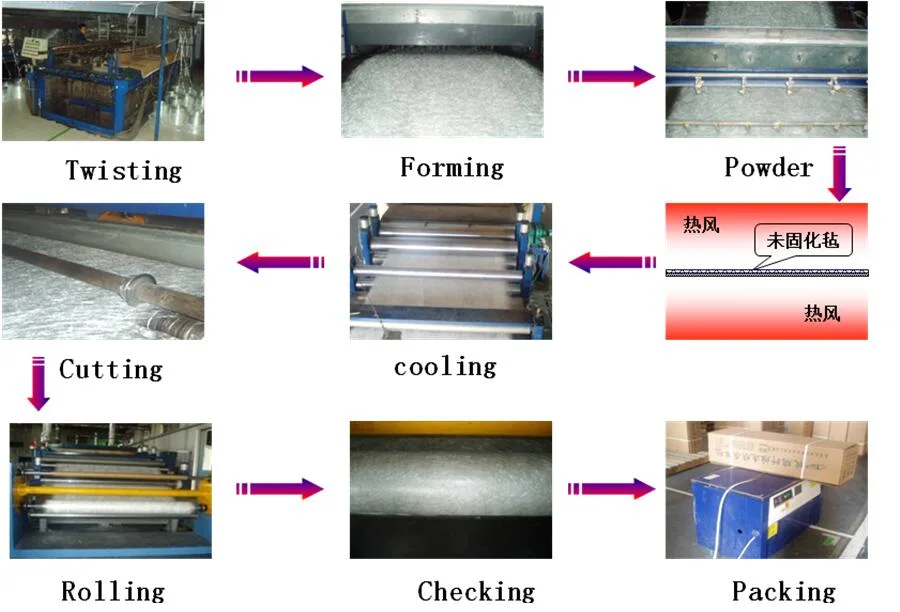

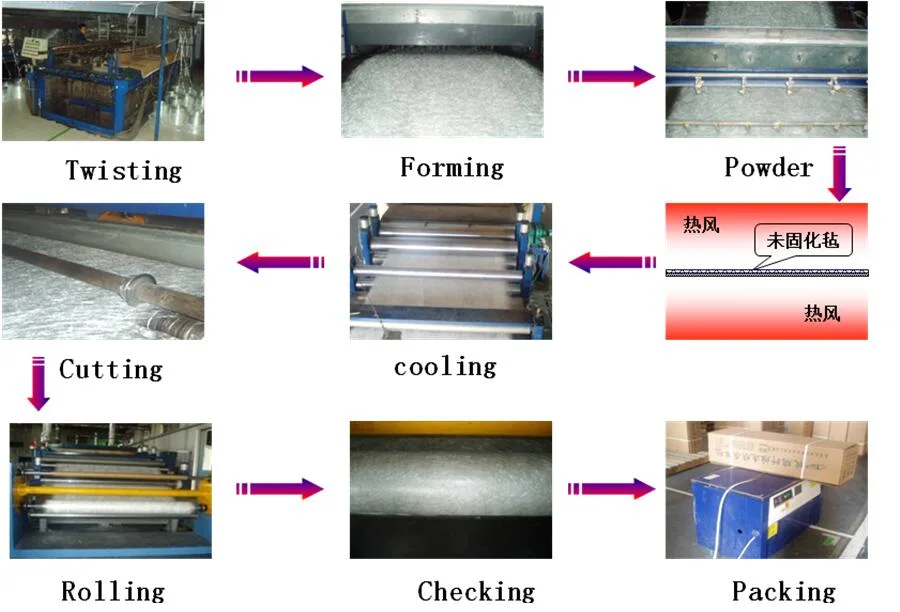

Production process

Detailed and Specific for fiberglass

Developing &Research

Test range: mechanical properties of materials, such as tensile strength, water content, with glue, weight and so on

Elongation, peel strength, flexural strength, flexural modulus, and so on .

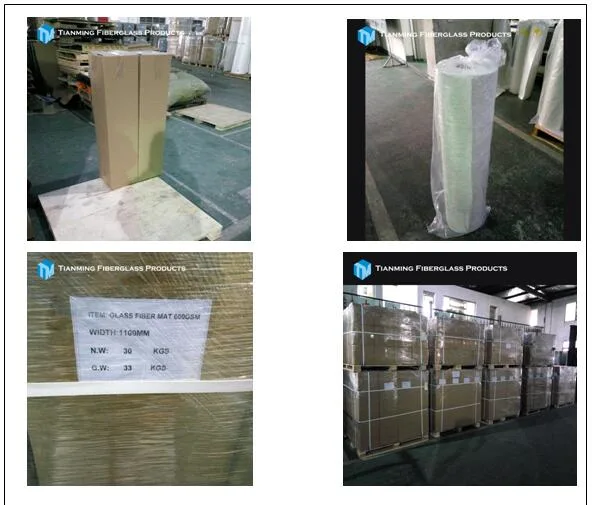

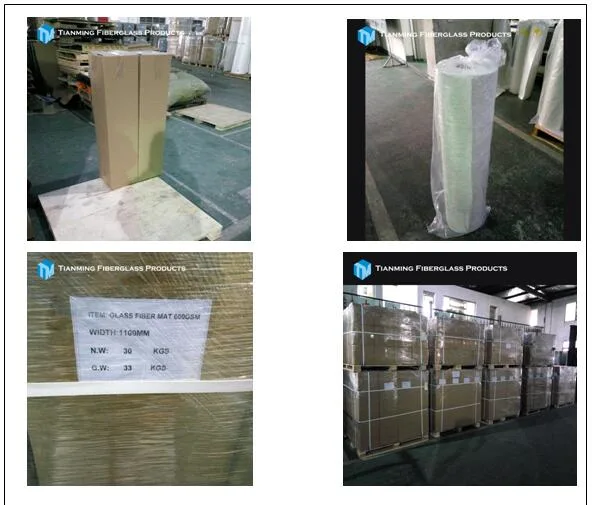

Packing

Kinds of packing way as follow :

Production Feature

1.Anti UV, anti aging, to solve the problem of aging products.

2. Improve the surface finish and beauty of products.

3. Suits any requirements of FRP.

4. Isotropic and mechanical capabilities great.

5. Easily molding and excellent compatibility with resin.

Application:

Storage:

Unless otherwise specified, fiberglass products should be stored in a dry, cool and moistureproof area. Room temperature and humidity should always be maintained at 15°C - 35°C, 35% - 65% respectively. Best used within 12 months after production date. Fiberglass products should remain in their original packaging until just prior to use.

Our Advantages:

1. Provide the high quality and low price product;

2. 24 hours online reply(English, Spanish and Chinese);

3. The most satisfying service Offered;

4. The safest package and transportation Offered;

5. Good after-sale service offered;

6.Your business relationship with us will be confidential to any third party.

FAQ:

Question 1: Are you a factory or a trade company?

Answer: We are manufacturer with more than 20 years production experience and have our top sales for the trade service.

Question 2: Can I try to get a sample before the order?

Answer: Sure. You can ask for the samples. Usually they're free.

Question 3: How about the lead time?

Answer: Within 5-7 days after getting the prepayment.

Question 4: Where is your factory located? How can I visit there?

Answer: Our factory is located in Nanjing, Jiangsu, China. You can fly to Nanjing airport directly.

Welcome to your visit!

Question 5:Can you customize the product according to our needs?

Answer:Of course,Our company has more than ten years of experienced R & D design team, can customize products according to your needs.

E glass / C glass Fiberglass Chopped Strand Mat for FRP products, Boat Building, Auto Parts

Chopped strand mat (or CSM as it is often known) is the most widely used of all composite reinforcement materials.Short strands of glass are randomly scattered and bound to create a mat which can then be wetted out with resin and used as a general purpose reinforcement for traditional fibreglass (GRP/FRP) moulds or parts.

Technical chat

Chopped Strand Mat technical chat

| Model No. | Weight | Width: | Loss on Ignition | Moistrure | Net Weight per Roll | Use And Craftwork | |||

| (oz. per sq.ft) | (grams per sq.m) | (inch) | (mm) | (%) | (%) | (lb) | (kg) | ||

| AEMC | 0.3-1 | 100-300 | 41-130 | 1040-3300 | 5-11 | ≤0.5 | 66 | 30 | Automotive headliner and oherss |

| AEMC | 0.7-3 | 225-900 | 41-130 | 1040-3300 | 4-6 | ≤0.5 | 66 | 30 | PHC process |

| EEMC | 1-2 | 300-600 | 41-130 | 1040-3300 | 4-6 | ≤0.2 | 66 | 30 | Specialized for Transformer |

| BEMC | 0.3-1 | 100-300 | 41-130 | 1040-3300 | 2-5 | ≤0.5 | 66 | 30 | Panel |

| FEMC | 0.3-2 | 100-600 | 41-130 | 1040-3300 | 2-7.5 | ≤0.5 | 66 | 30 | Hand Lay-up / FRP |

Production Line

Four different production line for kinds of Fiberglass

Production process

Detailed and Specific for fiberglass

Developing &Research

Test range: mechanical properties of materials, such as tensile strength, water content, with glue, weight and so on

Elongation, peel strength, flexural strength, flexural modulus, and so on .

Packing

Kinds of packing way as follow :

Production Feature

1.Anti UV, anti aging, to solve the problem of aging products.

2. Improve the surface finish and beauty of products.

3. Suits any requirements of FRP.

4. Isotropic and mechanical capabilities great.

5. Easily molding and excellent compatibility with resin.

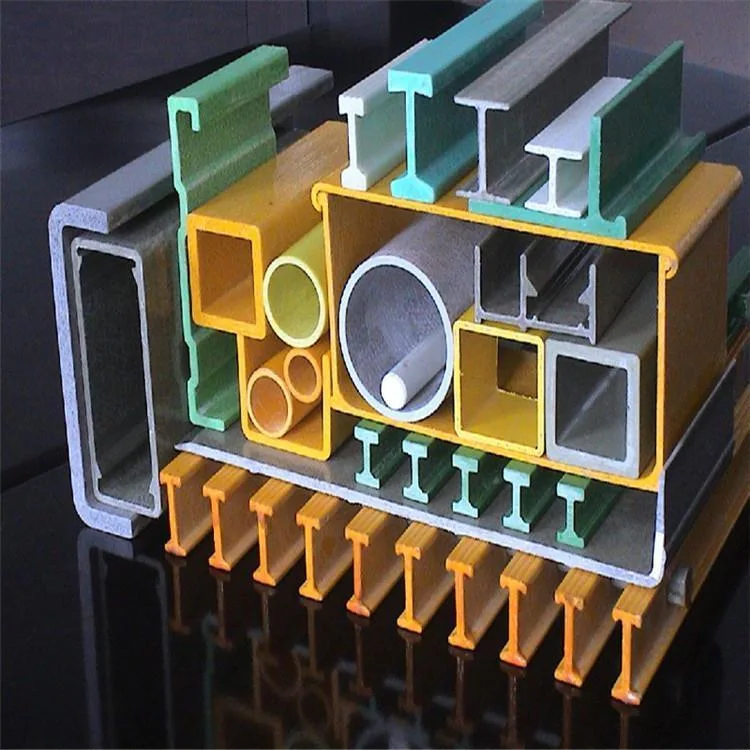

Application:

Storage:

Unless otherwise specified, fiberglass products should be stored in a dry, cool and moistureproof area. Room temperature and humidity should always be maintained at 15°C - 35°C, 35% - 65% respectively. Best used within 12 months after production date. Fiberglass products should remain in their original packaging until just prior to use.

Our Advantages:

1. Provide the high quality and low price product;

2. 24 hours online reply(English, Spanish and Chinese);

3. The most satisfying service Offered;

4. The safest package and transportation Offered;

5. Good after-sale service offered;

6.Your business relationship with us will be confidential to any third party.

FAQ:

Question 1: Are you a factory or a trade company?

Answer: We are manufacturer with more than 20 years production experience and have our top sales for the trade service.

Question 2: Can I try to get a sample before the order?

Answer: Sure. You can ask for the samples. Usually they're free.

Question 3: How about the lead time?

Answer: Within 5-7 days after getting the prepayment.

Question 4: Where is your factory located? How can I visit there?

Answer: Our factory is located in Nanjing, Jiangsu, China. You can fly to Nanjing airport directly.

Welcome to your visit!

Question 5:Can you customize the product according to our needs?

Answer:Of course,Our company has more than ten years of experienced R & D design team, can customize products according to your needs.