Basic Info.

Model NO.

HT00305

Standard Width

3.95m

Standard

Gri-GM 13 Standard, GB-I Standard

Standard Length

50m/100m

Hot-Selling Items

15kn-15kn/40kn-40kn

Transport Package

Plastic Roll

Specification

10KN/15KN/30KN/55KN

Trademark

HUATAO

Origin

China

HS Code

3926909090

Production Capacity

5000000 Square Meter /Week

Product Description

Plastic Polypropylene PP Biaxial Geogrids 20kn 30kn 40kn

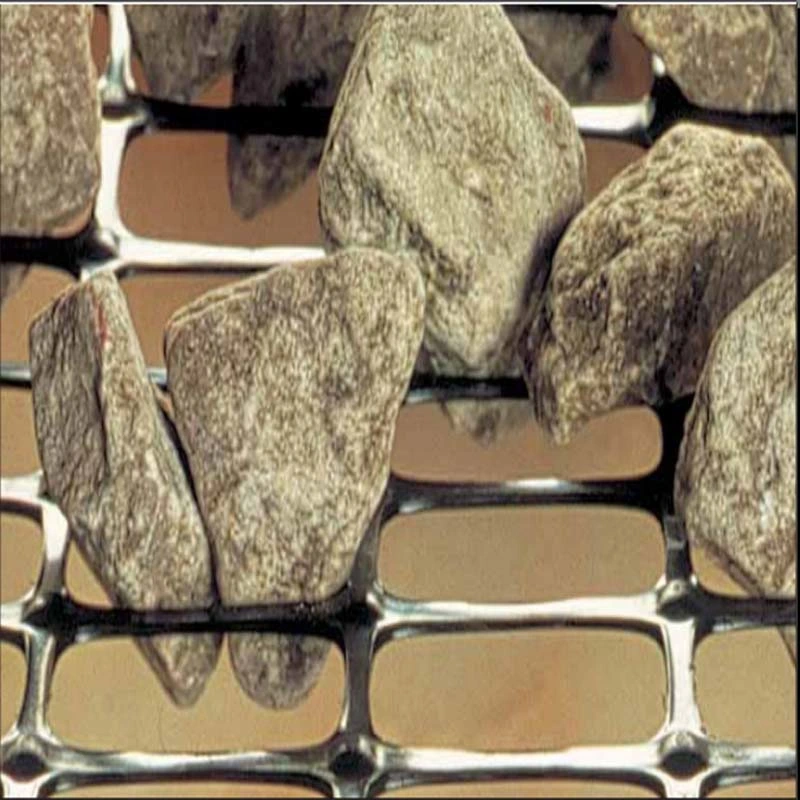

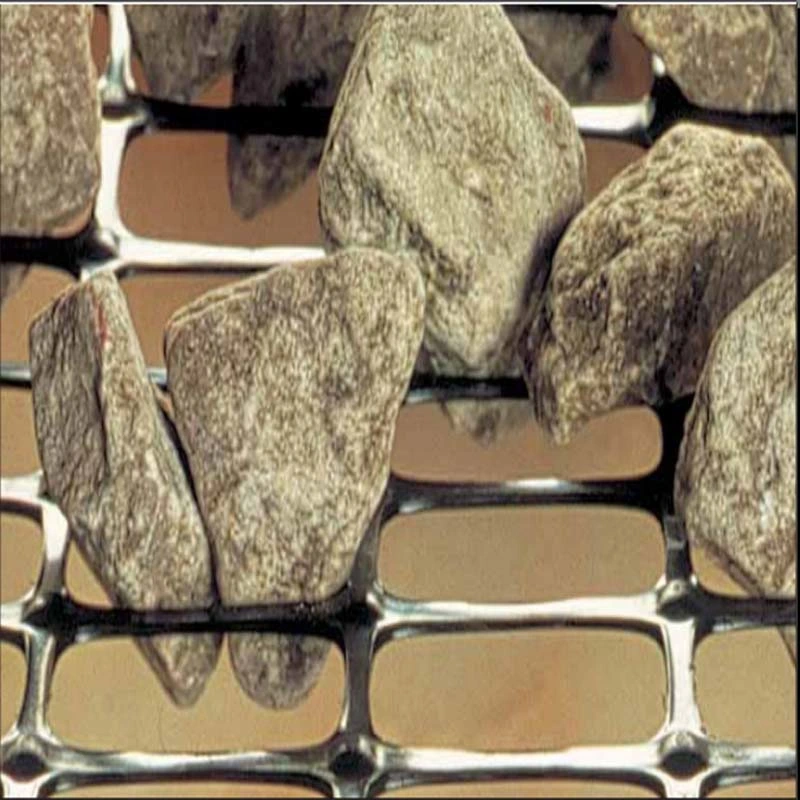

Plastic biaxial Geogrid Description

Two-way stretch plastic geogrid appearance approximate square network-like structure, which is made of polypropylene as the main raw material, by extrusion, and then vertical and horizontal stretching a high strength geotextile material. The material in the vertical and horizontal have great tensile strength, is widely used in soft foundation reinforcement treatment.

Plastic biaxial Geogrid specifications

1. Strength : 15/15KN/M -- 50/50KN/M

2. Width: from 2m - 6m

3. Length: as request

4. Package: paper core, black waterproof membrane

5. Loading: 20ft container, 40ft high container

Plastic biaxial Geogrid Datasheet

Plastic biaxial Geogrid Application

1, all kinds of roads, railways, airports roadbed enhancement;

2, permanent foundation bearing large car park and terminal freight yard and other enhancements;

3, railway, highway slope protection, culvert enhancement;

4-way stretch geogrid slope secondary enhanced enhanced, and further enhance the soil, prevent soil erosion;

5, mining, tunnel reinforcement.

Plastic biaxial Geogrid Construction

Excavation of foundation bed, set the sand cushion (height of not more than 10cm), rolled into the platform, laying grille, the vertical axis to be consistent with the direction of the main force, longitudinal lap 15-20cm, lateral 10cm, lap banding with plastic tape and laying on the grill every 1.5-2m with U-nails on the ground, laying geogrid should be promptly backfill material, laying geogrid layers depending on the technical requirements.

Plastic biaxial Geogrid Description

Two-way stretch plastic geogrid appearance approximate square network-like structure, which is made of polypropylene as the main raw material, by extrusion, and then vertical and horizontal stretching a high strength geotextile material. The material in the vertical and horizontal have great tensile strength, is widely used in soft foundation reinforcement treatment.

Plastic biaxial Geogrid specifications

1. Strength : 15/15KN/M -- 50/50KN/M

2. Width: from 2m - 6m

3. Length: as request

4. Package: paper core, black waterproof membrane

5. Loading: 20ft container, 40ft high container

Plastic biaxial Geogrid Datasheet

| No. | Specification | TGSG 15-15 | TGSG20-20 | TGSG30-30 | TGSG40-40 | TGSG45-45 | TGSG50-50 | TGSG60-60 |

| Mass g/m2 | 300±30 | 330±30 | 400±40 | 500±50 | 550±50 | 550±50 | ||

| 1 | Longitudinal tensile yield strength per meter KN/m ≥ | 15 | 20 | 30 | 40 | 45 | 50 | 60 |

| 2 | Transverse tensile yield force per meter KN/m ≥ | 15 | 20 | 30 | 40 | 45 | 50 | 60 |

| 3 | Yield longitudinal elongation %≤ | 16 | 17.5 | 21 | ||||

| 4 | Transverse Elongation Yield %≤ | 13 | 17.5 | 21 | ||||

| 5 | Longitudinal elongation 2% of the tensile force KN/m ≥ | 5 | 8 | 11 | 13 | 16 | 22 | 25 |

| 6 | Horizontal elongation rate 2% of tensile strength KN/m ≥ | 7 | 10 | 13 | 15 | 20 | 32 | 35 |

| 7 | Longitudinal elongation 5% of the tensile force KN/m ≥ | 8 | 10 | 15 | 16 | 25 | 35 | 39 |

| 8 | Horizontal elongation rate 5% of tensile strength KN/m ≥ | 10 | 13 | 15 | 20 | 22 | ||

Plastic biaxial Geogrid Application

1, all kinds of roads, railways, airports roadbed enhancement;

2, permanent foundation bearing large car park and terminal freight yard and other enhancements;

3, railway, highway slope protection, culvert enhancement;

4-way stretch geogrid slope secondary enhanced enhanced, and further enhance the soil, prevent soil erosion;

5, mining, tunnel reinforcement.

Plastic biaxial Geogrid Construction

Excavation of foundation bed, set the sand cushion (height of not more than 10cm), rolled into the platform, laying grille, the vertical axis to be consistent with the direction of the main force, longitudinal lap 15-20cm, lateral 10cm, lap banding with plastic tape and laying on the grill every 1.5-2m with U-nails on the ground, laying geogrid should be promptly backfill material, laying geogrid layers depending on the technical requirements.