Basic Info.

Model NO.

QX

Roll Width

1270mm

Transport Package

in Cartons

Specification

600-1600

Trademark

JLON

Origin

China

HS Code

70195900

Production Capacity

2000 Ton/Month

Product Description

Introduction:

Multiaxial fabrics consists of one or more layers of long fiber in direction of 0°,90 °,+45°,-45°, with or without chopped mat and layer of veil. These layers are stitched with polyester yarn.

Typical applications of multiaxial fabric are wind energy, marine/ship building, sport/leisure products, automotive, aerospace & defence, etc.

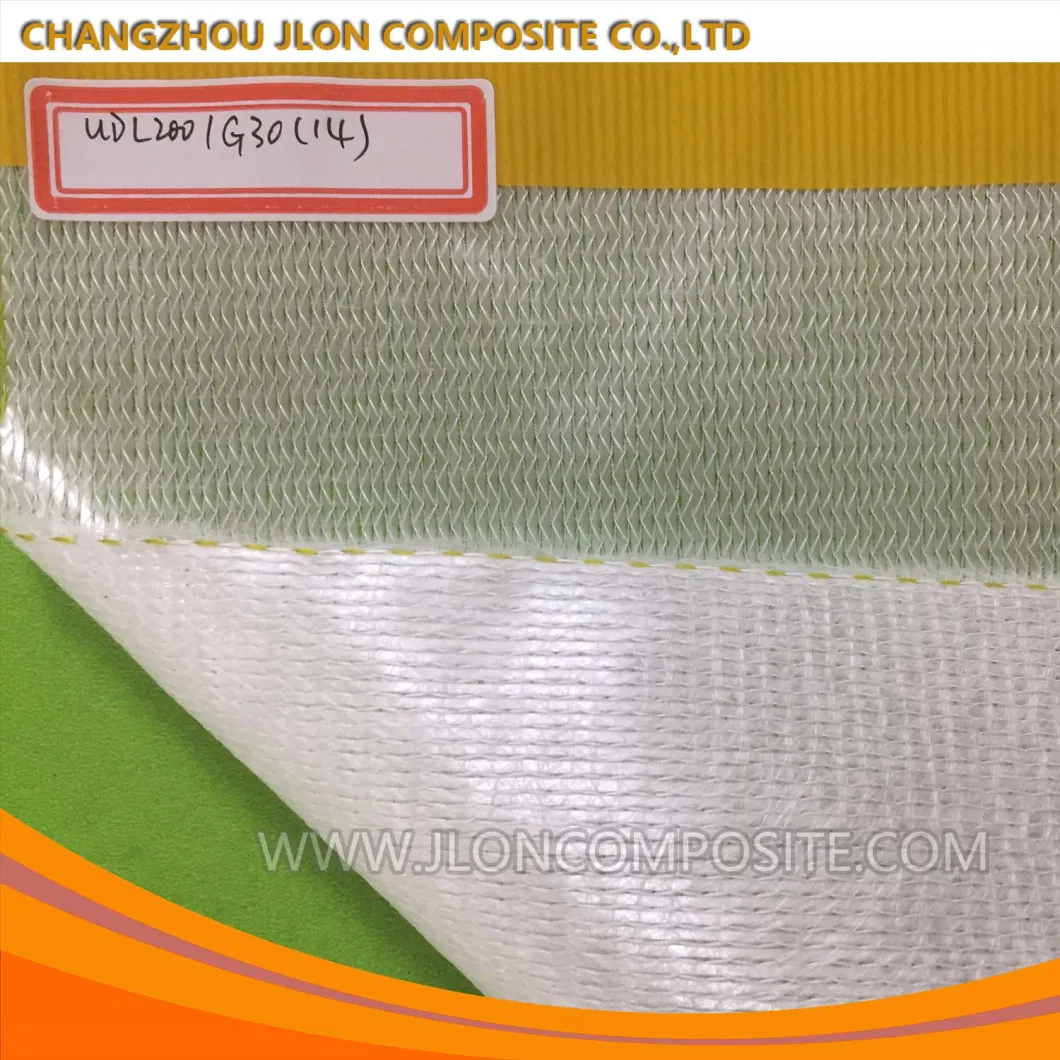

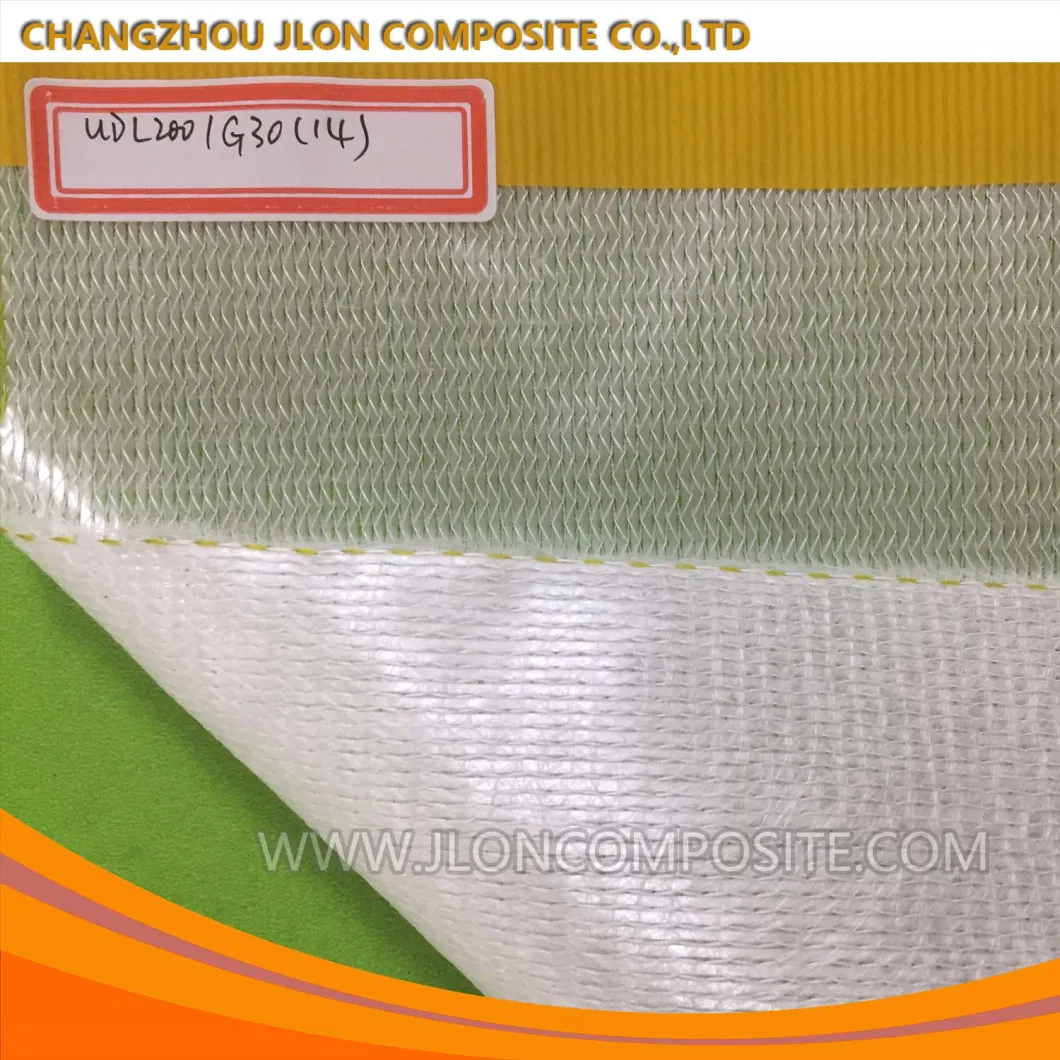

Unidirectional Fabric:

A unidirectional (UD) fabric can be made as 0° orientation or 90° orientation. The UD fabrics have high strength in one direction.

Double Bias or Bi-Axial fabric:

Double Bias fabrics are continuous roving oriented in the +45° and -45° directions. They offer superior structural performance in applications subject to extreme shear and torsion stress. These properties are ideal for applications such as wind blades, marine panels, and snowboards

Bi-Directional Fabric:

The bidirectional fabrics are made by stitching two layers in 0° & 90° directions. They are Non crimp fabric and provide excellent fatigue resistance. Less resin is consumed compared with woven fabric.

Triaxial Fabric :

Triaxial fabrics are a three layer construction fabric, there are two styles in Triaxial- one has a fiber orientation of (+45°/90°/-45°) and the other has a fiber orientation of (0°/+45°/-45°). Triaxial fabrics are used for high strength application.

Quadraxial Fabric :

Quadraxial fabric consists of all layers (0°/+45°/90°/-45°) of roving orientation. This fabric provides strength in all direction. And this fabric can be produced with the maximum aerial density when compared to any other fabric style.

Multiaxial fabrics consists of one or more layers of long fiber in direction of 0°,90 °,+45°,-45°, with or without chopped mat and layer of veil. These layers are stitched with polyester yarn.

Typical applications of multiaxial fabric are wind energy, marine/ship building, sport/leisure products, automotive, aerospace & defence, etc.

Unidirectional Fabric:

A unidirectional (UD) fabric can be made as 0° orientation or 90° orientation. The UD fabrics have high strength in one direction.

| Product No. | Overall Density (g/m²) | 0º Roving Density (g/m²) | 90º Roving Density (g/m²) | Chop Density (g/m²) | Polyester Yarn Density (g/m²) |

| UDL300 | 312 | 261 | 39 | / | 12 |

| UDL400 | 412 | 355 | 45 | / | 12 |

| UDL460 | 469.5 | 413 | 47 | / | 9.5 |

| UDL600A | 612 | 533 | 67 | / | 12 |

| UDL600 | 612 | 480 | 120 | / | 12 |

| UDL800 | 812 | 710 | 90 | / | 12 |

| UDL950 | 956 | 866 | 84 | / | 6 |

| UDL1000 | 1022 | 710 | / | 300 | 12 |

| UDL1200 | 1195 | 1134 | 55 | / | 6 |

| UDT125 | 126 | / | 120 | / | 6 |

| UDT300 | 309.5 | / | 300 | / | 9.5 |

| UDT500 | 509.5 | / | 250 | / | 9.5 |

| UDT600 | 609.5 | / | 600 | / | 9.5 |

| UDTM225/225 | 459.5 | / | 225 | 225 | 9.5 |

| UDTM300/300 | 609.5 | / | 300 | 200 | 9.5 |

| UDTM600/300 | 909.5 | / | 600 | 300 | 9.5 |

Double Bias or Bi-Axial fabric:

Double Bias fabrics are continuous roving oriented in the +45° and -45° directions. They offer superior structural performance in applications subject to extreme shear and torsion stress. These properties are ideal for applications such as wind blades, marine panels, and snowboards

Product No. | Overall Density (g/m²) | +45º Roving Density (g/m²) | -45º Roving Density (g/m²) | Chop Density (g/m²) | Polyester Yarn Density (g/m²) |

| BX160 | 172 | 80 | 80 | / | 6 |

| BX240 | 233 | 106 | 106 | / | 6 |

| BX300 | 306.7 | 150.33 | 150.33 | / | 6 |

| BX400 | 407 | 200.5 | 200.5 | / | 6 |

| BX450 | 457 | 225.5 | 225.5 | / | 6 |

| BX600 | 607.2 | 300.6 | 300.6 | / | 6 |

| BX800 | 807.6 | 400.8 | 400.8 | / | 6 |

| BX1200 | 1208.6 | 601.3. | 601.3 | / | 6 |

| BXM400/225 | 632 | 200.5 | 200.5 | 225 | 6 |

| BXM600/225 | 832.2 | 300.6 | 300.6 | 225 | 6 |

| BXM800/450 | 1257.6 | 400.8 | 400.8 | 450 | 6 |

| BXM1208 | 682 | 200.5 | 200.5 | 275 | 6 |

| BXM1308 | 732 | 225.5 | 225.5 | 275 | 6 |

| BXM1708 | 882.2 | 300.6 | 300.6 | 275 | 6 |

| BXM2408 | 1082.6 | 400.8 | 400.8 | 275 | 6 |

Bi-Directional Fabric:

The bidirectional fabrics are made by stitching two layers in 0° & 90° directions. They are Non crimp fabric and provide excellent fatigue resistance. Less resin is consumed compared with woven fabric.

Product No. | Overall Density (g/m²) | 0º Roving Density (g/m²) | 90º Roving Density (g/m²) | Chop Density (g/m²) | Polyester Yarn Density (g/m²) |

| LT400 | 409.5 | 202 | 198 | / | 9.5 |

| LT600 | 609.5 | 330 | 270 | / | 9.5 |

| LT800 | 809.5 | 412.5 | 387.5 | / | 9.5 |

| LT1200 | 1209.5 | 605 | 595 | / | 9.5 |

| LTM400/200 | 609.5 | 202 | 198 | 200 | 9.5 |

| LTM600/300 | 909.5 | 330 | 270 | 300 | 9.5 |

| LTM600/450 | 1059.5 | 330 | 270 | 450 | 9.5 |

| LTM800/250 | 1059.5 | 412.5 | 387.5 | 250 | 9.5 |

| LTM800/300 | 1109.5 | 412.5 | 387.5 | 300 | 9.5 |

| LTM800/450 | 1259.5 | 412.5 | 387.5 | 450 | 9.5 |

| LTM1608 | 835.5 | 275 | 276 | 275 | 9.5 |

| LTM1808 | 894.5 | 330 | 280 | 275 | 9.5 |

| LTM2408 | 1092 | 412.5 | 395 | 275 | 9.5 |

| LTM2415 | 1274.7 | 412.5 | 395 | 457.7 | 9.5 |

| LTM3208 | 1381.5 | 605 | 492 | 275 | 9.5 |

Triaxial Fabric :

Triaxial fabrics are a three layer construction fabric, there are two styles in Triaxial- one has a fiber orientation of (+45°/90°/-45°) and the other has a fiber orientation of (0°/+45°/-45°). Triaxial fabrics are used for high strength application.

Product No. | Overall Density (g/m²) | 0º Roving Density (g/m²) | +45º Roving Density (g/m²) | 90º Roving Density (g/m²) | -45º Roving Density (g/m²) | Chop Density (g/m²) | Polyester Yarn Density (g/m²) |

| TXL450 | 453.2 | 144.7 | 150.3 | 1.91 | 150.3 | / | 6 |

| TXL600 | 613.8 | 217.1 | 194.4 | 1.91 | 194.4 | / | 6 |

| TXL750 | 754 | 216 | 265 | 1.91 | 265 | / | 6 |

| TXL800 | 811.8 | 394 | 200.4 | 11 | 200.4 | / | 6 |

| TXL1200 | 1176.1 | 567 | 300.6 | 1.91 | 300.6 | / | 6 |

| TXT450 | 456 | 0 | 68 | 314 | 68 | / | 6 |

| TXTV450/45 | 501 | 0 | 100 | 250 | 100 | V45 | 6 |

| TXT480 | 481.3 | 0 | 158.1 | 159.1 | 158.1 | / | 6 |

| TXT750 | 751.5 | 0 | 202 | 341.5 | 202 | / | 6 |

| TXT800 | 810.3 | 1.91 | 200.4 | 401.6 | 200.4 | / | 6 |

| TXT1050 | 1055.9 | 1.91 | 217 | 614 | 217 | / | 6 |

| TXT1200A | 1214.6 | 1.91 | 400.8 | 405.1 | 400.8 | / | 6 |

| TXT1200 | 1358.8 | 1.91 | 300.6 | 640 | 300.6 | / | 6 |

Quadraxial Fabric :

Quadraxial fabric consists of all layers (0°/+45°/90°/-45°) of roving orientation. This fabric provides strength in all direction. And this fabric can be produced with the maximum aerial density when compared to any other fabric style.

Product No. | Overall Density (g/m²) | 0º Roving Density (g/m²) | +45º Roving Density (g/m²) | 90º Roving Density (g/m²) | -45º Roving Density (g/m²) | Chop Density (g/m²) | Polyester Yarn Density (g/m²) |

| QK600 | 601.4 | 144.7 | 150.4 | 150 | 150.4 | / | 6 |

| QK800 | 823.8 | 216 | 200.5 | 200.8 | 200.5 | / | 6 |

| QK1000 | 954 | 216 | 248 | 236 | 248 | / | 6 |

| QK1150 | 1178.7 | 294 | 300.6 | 283.5 | 300.6 | / | 6 |

| QK1200 | 1201.2 | 294 | 300.6 | 300 | 300.6 | / | 6 |

| QK1600 | 1620 | 434 | 308 | 564 | 308 | / | 6 |