Basic Info.

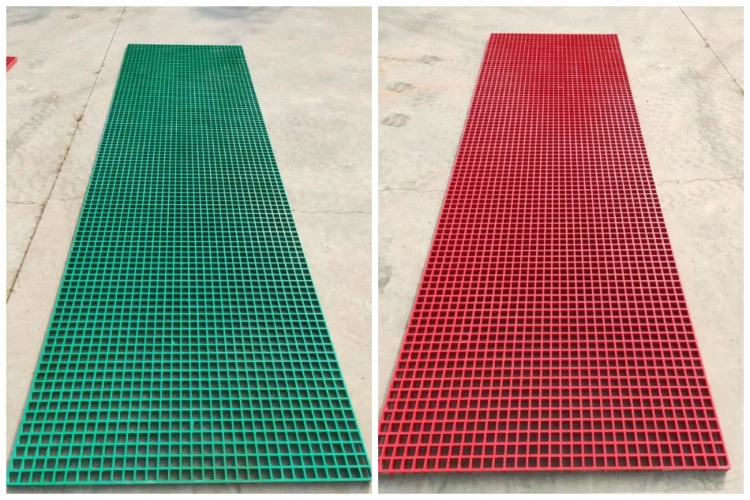

Product Description

FRP Molded Grating is made from polyester resin and continuous fiberglass roving, heat cured in a mold, in a hand-crafted layer-by-layer operation to produce the desired thickness and panel size. Grating produced using this technique have 30-35% (total weight) glass fiber reinforcement. The one-piece interwoven mesh construction of the molded grating produces a product with optimal corrosion resistance and bi-directional strength. Since the grating is "cast" in one piece, there is no mechanical joint between bearing bars, unlike pultruded grating where the glued joints can give way in heavy continuous traffic or after prologged service.

The high percentage of resin (65%) in molded grating provides superior corrosion resistance and optimal impact resistance. Molded fiberglass gratings with a square mesh pattern offer increased load capacity and panel utilization due to its bi-directional nature.

And for different application, the surface can be chosed from smooth, concave, gritted or solid-top.

Specification for FRP grating is as following:

| Fiberglass Reinforced Plastic (FRP) Gratings | ||||||

| Type | Mesh Size (mm) | Height (mm) | Bar Thickness (mm) | Full Panel Size (m) | Net Weight (Kg/m²) | Load-bearing |

| 20 | 50*50 | 20 | The upper thickness is 7, and the lower thickness is 5 | 1.22*3.66 | 8 | trench cover |

| 25 | 43*43 | 25 | 1.22*3.66 | 11 | Stair treads/tree grates/load-bearing walking bicycles | |

| 40*40 | 25 | 1.22*3.66 | 11 | |||

| 38*38 | 25 | 1.22*3.66 | 12 | |||

| 30 | 40*40 | 30 | 1.22*3.66 | 16 | drainage ditch,span<30cm and bearing 1.5 ton,span<50cm and bearing 1 ton | |

| 38*38 | 30 | 1.22*3.66 | 17 | |||

| 38 | 40*40 | 38 | 1.22*3.66 | 20 | platform,span<30cm and bearing 3 ton | |

| 38*38 | 38 | 1.22*3.66 | 22 | |||

| 50 | 50*50 | 50 | 1.22*3.66 | 24 | gutter drainage ditch,span<30cm and bearing 4 ton | |

| 38*38 | 50 | 1.22*3.66 | 26 | |||

| 25 crossed grid | 50*25 | 25 | 1.22*3.66 | 13 | breeding,span<30cm and bearing 0.8 ton,span<50cm and bearing 0.3 ton | |

| 38*19 | 25 | 1.22*3.66 | 17 | |||

| 30 crossed grid | 50*25 | 30 | 1.22*3.66 | 18 | platform,span<30cm and bearing 1 ton,span<50cm and bearing 0.5 ton | |

Features of our fiberglass gratings:

- High Strength

- Light Weight

- Fire Retardant

- Corrosion Resistant

- UV Resistance and Anti-aging

- High Impact and Fatigue Strength

- Non Conductive, Low Thermal Conductivity

- Cost Effective, Easy to Install and Maintenance

Application for Molded Frp Grating FRP GRP Grating Fiberglass Floor Grills Glass Fiber Reinforced Plastic Molded Grille

FRP gratings are usually used as floor grating, marina walkway, roof walkway, catwalk grating, work platforms, offshore platforms, decks, stair treads, fencing, tree guard, drain channel cover, ditch covers, etc.

And they are widely used in petroleum, water conservancy, textile printing and dyeing, food processing, electronics industry, sewage treatment, shipbuilding, civil construction, power engineering, power substations, and chemical industries.

To find the specification and more detailed properties of our FRP grating, please feel free to contact us.

Package for FRP molded grating:

1. For FRP grating, we always pack them on pallet with film wrap and corner guard protect.

2. We can do customized package as your requirement.