Basic Info.

Material

Polybutylene Terephthalate/PBT

Usage

General Plastics, Engineering Plastics, Specialty Plastics

Plastic Properties After Heated

Thermoplastic Plastics

Plastic Forming Method

Injection

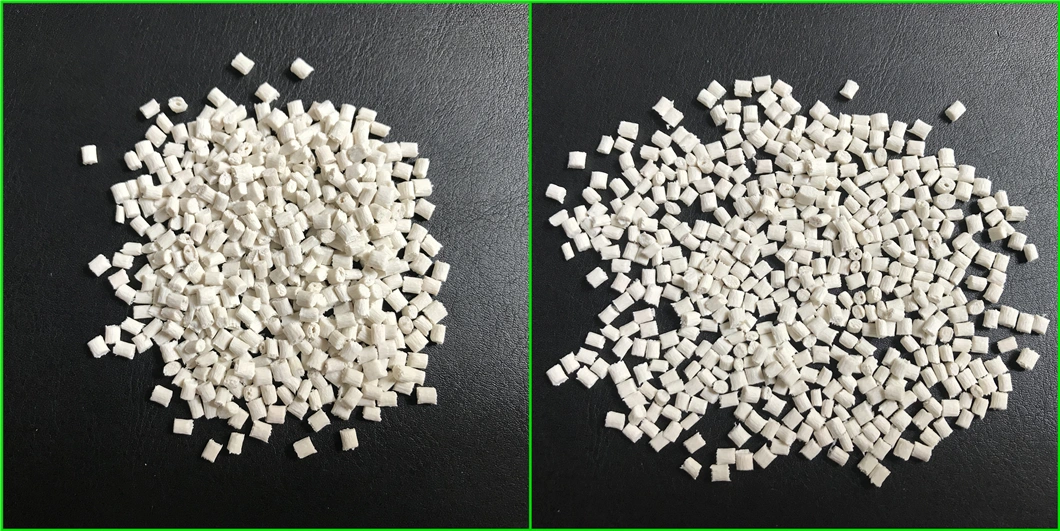

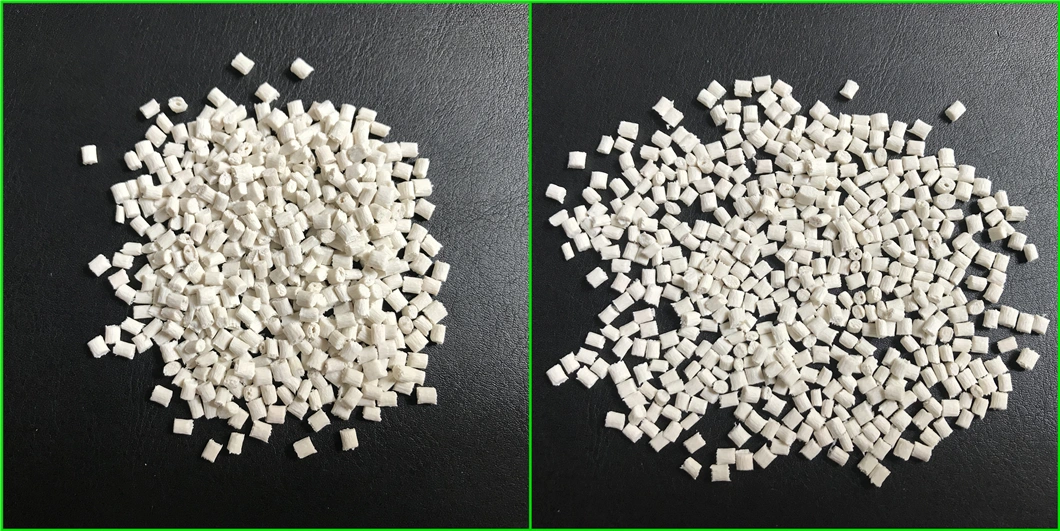

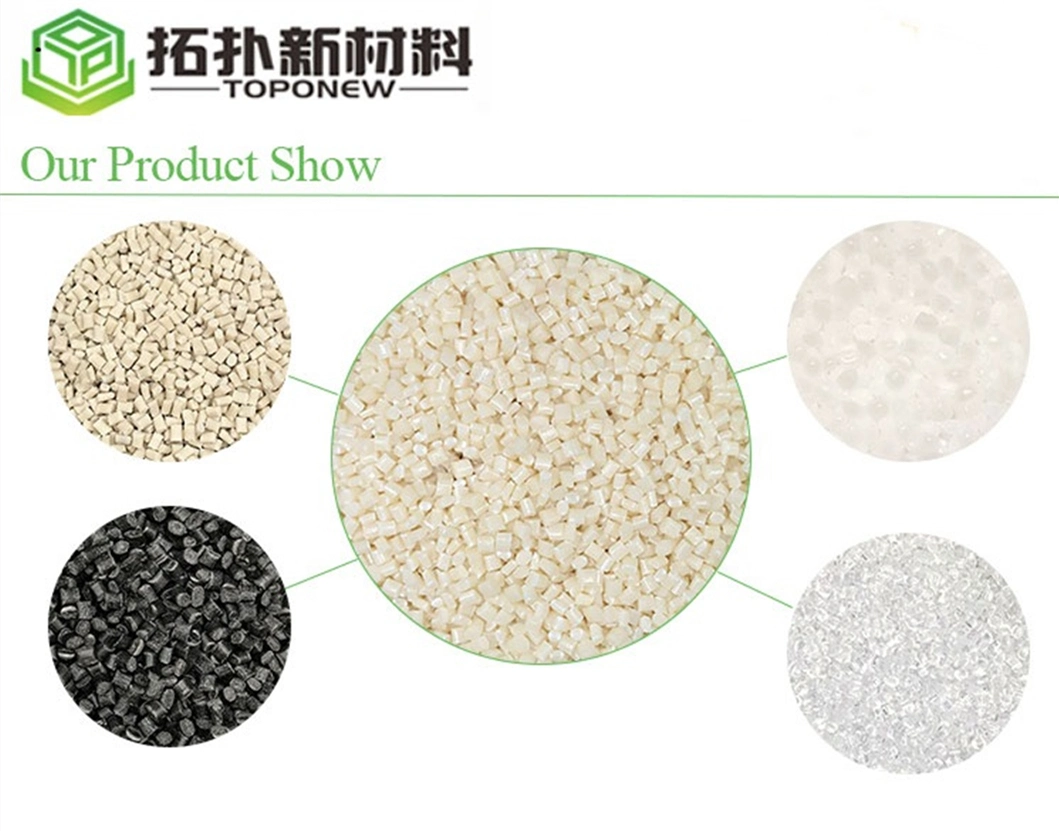

Color

White

Shape

Granules/Pellets

Sample

Avalible

Delivery Time

5-7 Working Days

Grade

Injection

Filler Content

10-30%

Density

1.16-1.58

Transport Package

25kg/Bag

Specification

65*40*15cm

Trademark

TOPO NEW

Origin

China

HS Code

3907991001

Production Capacity

100kgs/Week

Packaging & Delivery

Package Size

65.00cm * 40.00cm * 15.00cm

Package Gross Weight

25.000kg

Product Description

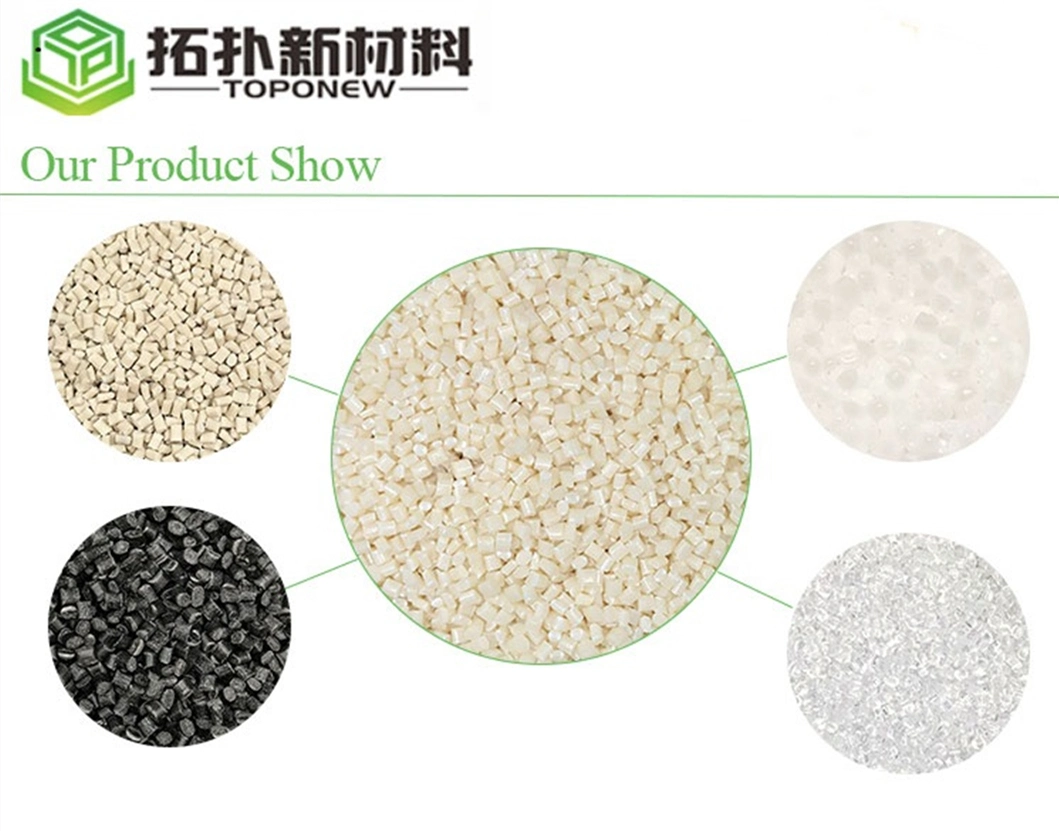

Injection Vrigin-grade mouth mirror handle cover Glass fiber filled PBT resin/compound

PBT Polyethylene Terephthalate (D0715)

PBT Polyethylene Terephthalate (D0715)

| GRADE | FEATURES | APPLICATION |

| GF Reinforced PBT | 10%-50% GF reinforced, high strength, low warpage. | Electric cooker, soybean milk and juice maker and other home appliances, air condition shell, car accessories, fan heater, instrument panel, thermal jug... New Energy vehicle charging pile and charging gun, automotive, MCB, appliance parts, low-temperature resistant nylon tie band, power tools, office chair base, hydrant handle, ski equipment components, breaker, connector... Battery cell jar case, heating appliances case, panel, plug, electronic shell, instrument frame, auto parts and etc... |

| Flame Retardant PBT | Fire resistant V0-5VA, high toughness, easy de-molding. | |

| High-Temperature PBT | High temperature resistant 108-115 degrees centigrade. |

PBT Polyethylene Terephthalate (D0715)

PBT Polyethylene Terephthalate (D0715) | Product Description | Applications | ||||||||

| ·30%PBT 30% glass fiber reinforced PBT | · Injection molding | ||||||||

| · Excellent heat stability | · Good mechanical properties balance | ||||||||

| Properties | Test Method | Test Condition | Unit | Typical Values | |||||

| Physical properties | |||||||||

| Specific Gravity | ISO 1183 | 23ºC | g/cm3 | 1.41 | |||||

| Ash | ISO 3451 | 800ºC,30min | % | 15 | |||||

| Mechanical properties | |||||||||

| Tensile Strength | ISO 527 | 50mm/min | MPa | 140 | |||||

| Elongation at Break | ISO 527 | 50mm/min | % | 2.5 | |||||

| Tensile Modulus | ISO 527 | 1mm/min | MPa | 215 | |||||

| Flexural Modulus | ISO 178 | 2mm/min | MPa | 3200 | |||||

| Charpy Notched Impact Strength | ISO 179-1eA | 23ºC | kJ/m2 | 11.4 | |||||

| Thermal properties | |||||||||

| Heat deflection temperature | ISO 75 | 1.80MPa | C | 210 | |||||

| Other properties | |||||||||

| Flammability | UL94 | - | HB | ||||||

| Note: The data above is a typical value for reference, not a guaranteed value. The data will vary with tool design such as gate type, gate location, gate number, injection molding process, and part thickness. The data will vary with different colors as well. Prior to using the material, please consult with TOPO Co., Ltd | |||||||||

Are you a trading company or manufacturer?

We are manufacturer.

About Sample?

A 5 KG Free Sample can be offered per your request.

About Material Color?

We can make the material to your appointed color according to Pantone/RAL#.

How does your factory control the quality?

Quality is the Priority, we always pay great importance to quality from beginning to end, and we have professional QC for item quality from spare parts to finished goods.

How many days for mass production?

20 days after all artwork and 30% deposit are confirmed.

How can I get the samples? is the sample free?

7-10 days to send free samples by DHL, TNT, and UPS.