- Overview

- Basic Information

- Specification

- Sample Display

- Visit & Exhibition

- Packaging & Shipping

Basic Info.

Model NO.

R3/R3 Plus

Structure Type

Desktop

Laser Classification

Fiber Laser

Laser Technology

Laser Fusion Cutting

Length of Tube

6000mm

Processing Material

Ss CS Metal Aluminium Iron Copper Alloy

After-Service

Online Support & Local Service

Control System

Hsg-X9000 Bus CNC System

Tailing

85mm

Transport Package

Vacuum-Packed

Specification

8627*2230*2100mm

Trademark

HSG Laser/Xlaser

Origin

China

Product Description

| Laser Cutting Machines of a Great Variety--HSG Laser HSG Laser can serve global users with 20+ kinds of machines that are suitable for most materials needing to be cut, including sheet metal laser cutting machine, sheet & tube laser cutting machine, tube metal laser cutting machine, bending machine and welding machine. The following is the introduction of a type of Economical Pipe metal Cutting Machine: |

Economical Tube Laser Cutting Machine 1500W-4000W

* Machine appearance, technical parameters, function description, data comparison shown in this page are from HSG in-house laboratory.

All testing results and experimental data shall be subject to real machine.

Economical Model

Small size and small occupied area, improving the utilization of workshop.

Shipped in a 40HQ standard container with no need for metal plate removal.

Shipped in a 40HQ standard container with no need for metal plate removal.

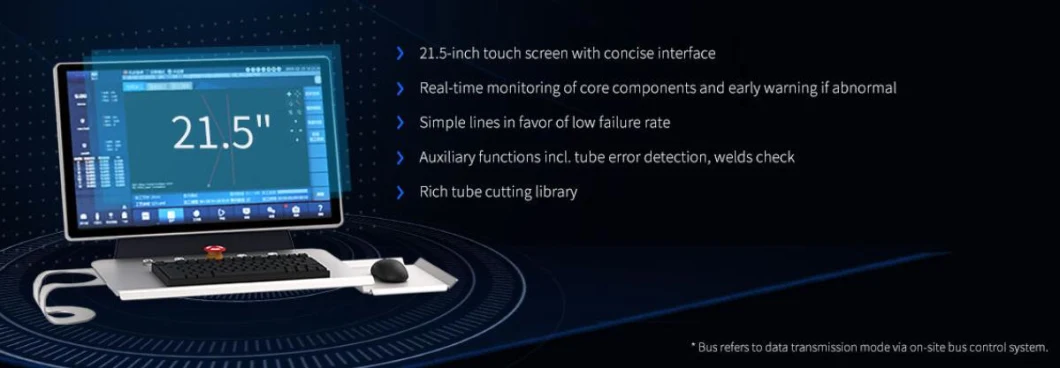

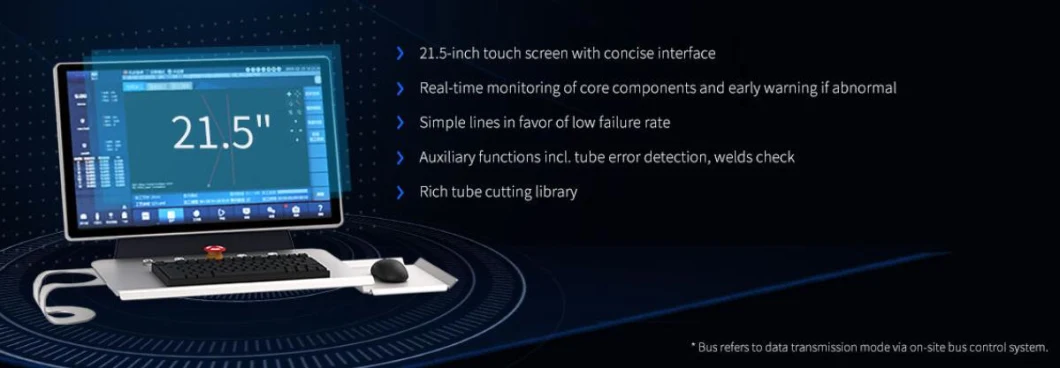

HSG-X9000 Bus CNC System

KLINGE Autofocus Cutting Head

KLINGE, made of stainless steel, has a function of water cooling, dual-path cooling nozzle, ceramic ring,

double focusing protective lens, drawer-type pluggable protective lens, focusing and collimating lens.

Self-developed by HSG LASER

Autofocus accuracy ±0.01mm

Flow control for mirror-like surface cutting

Prevent spark splashing and scalds by SS protective pipes

Double Pneumatic Chucks

Detecting sensor for front and rear chuck opening & clamping, preventing possible collision.

Function of front chuck ventilation, for dust prevention from entry into chucks.

Front chuck avoidance cutting. Function of front chuck ventilation, for dust prevention from entry into chucks.

Applications

HSG Fiber Laser Cutting Machines are widely used in Manufacture Billboard, Signs, Advertising, Signage, Metal Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal Crafts, Metal Art Ware, Elevator Panel Cutting, Hardware, Auto Parts, Glasses Frame, Electronic Parts Nameplates, etc.

Technical Parameter

| Model | R3 | R3 PLUS |

| Power | 1500-4000W | |

| X/Y-axis Positioning Accuracy | ±0.03mm/m | |

| X/Y-axis Repositioning Accuracy | ±0.03mm | |

| No-load Speed | 90m/min | |

| Acceleration | 0.8G | |

| Rotating Speed of Chucks | 90r/min | |

| Cutting Capacity of Round Tube | 20-220mm | 20-325mm |

| Cutting Capacity of Square Tube | 20*20mm-150*150mm | 20*20-230*230mm |

| Length of Tube | 6000mm | |

| Weight of Single Tube | 150kg | 200kg |

| Tailing | 85mm | |

| Overall Dimensions (L*W*H) | 10000*4500*2350mm | 10160*4600*2350mm |

| * Machine appearance, technical parameters, function description, data comparison shown in this page are from HSG in-house laboratory. All testing results and experimental data shall be subject to real machine. | ||

1. Our high-standard package include aluminum foil, metal framework, fumigation wooden case, anti-rust oil+oilpaper, moisture-barrier bag, waterproof plastic film and filling foam, in order to satisfy ocean shipping criteria.

2. We will ensure they can be delivered to customers ASAP. withour damage.

2. We will ensure they can be delivered to customers ASAP. withour damage.

3. We also support a variety of transportation methods.