Basic Info.

Model NO.

HW-3851

Customized

Non-Customized

Condition

New

After-sales Service

1 Year

Speed

1200rpm

Weft Density

5-60 Thread/M

Reed Space

150 170 190 210 230 260 280 300 320 340 360

Weft Insertion Rate

2280m/Min

Transport Package

Plastic Protection Package

Specification

SGS

Trademark

HJ

Origin

Qingdao China

HS Code

84463040

Production Capacity

11000sets/Year

Product Description

Qingdao Haijia Machinery is the governing units of Chinese Textile Machinery!

It's sales champion for 15 consecutive years in China Water Jet Loom's industry!

Haijia machine is China No. 1 brand in the textile field.

More than 80000 sets machine are running successfully.

21 years experience in manufacturing textiles.

Annual capacity of 8000 sets.

28% of the total global market, global one!

HW-3851# Cam Shedding Device Specification

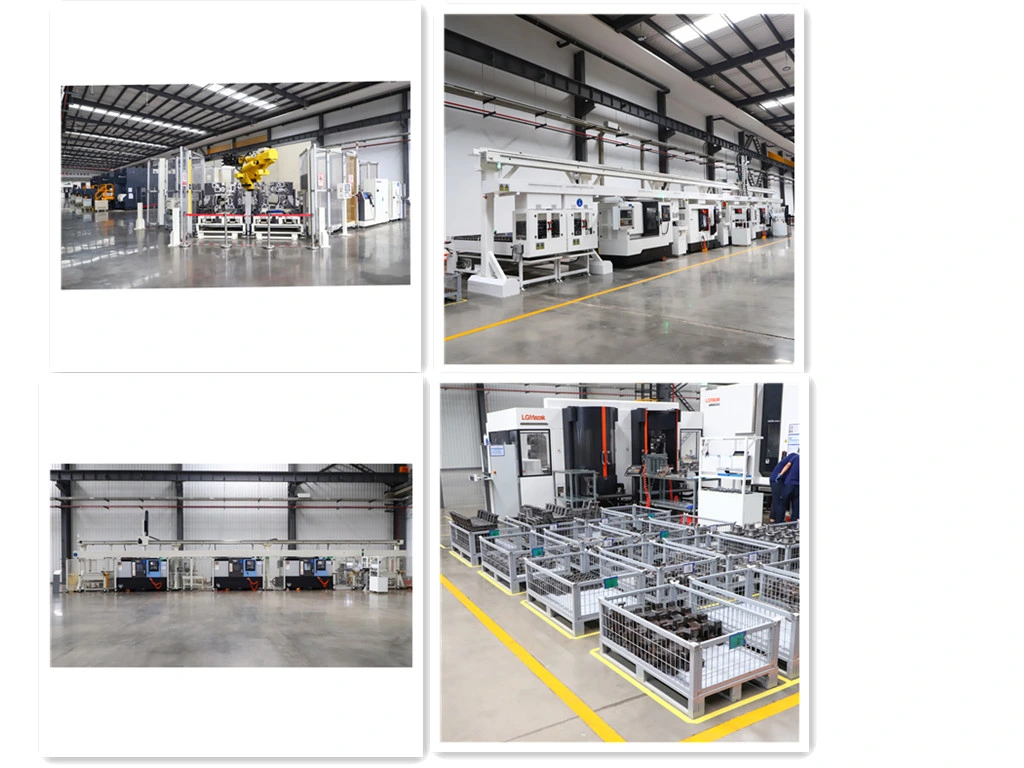

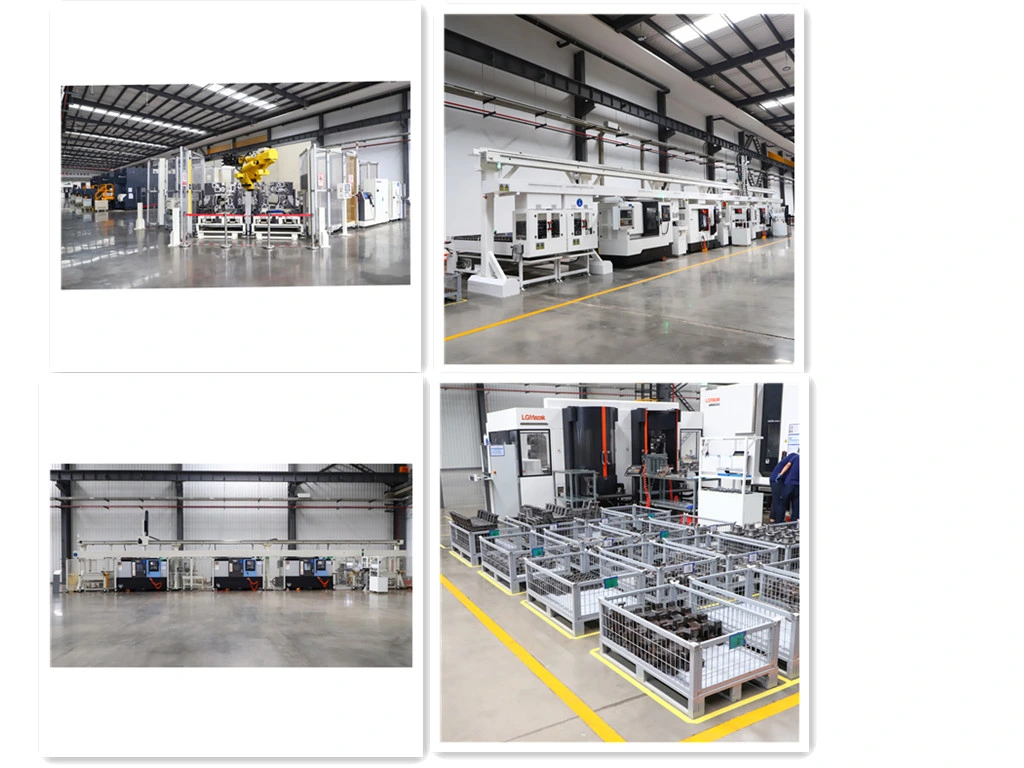

The CNC Workshop in Our Factory Introduction

Advanced Manufacturing Workshop

The company is equipped with advanced CNC equipment, high-precision imported processing center, and adopts information management methods to achieve independent precision machining of precision parts of key parts of the loom. The processing accuracy of key parts and components reaches 0.01mm,greatly improving the whole machine Stability and startup efficiency.

Three Dimensions Warehouse

Three Dimensions Warehouse

The company is equipped with an automated three-dimensional warehouse, which uses computers to accurately manage the goods information, reducing possible errors in the process of storing goods and improving work efficiency. At the same time, the three-dimensional automated warehouse realizes motorization in the transportation of goods in and out of the warehouse, which is safe and reliable in handling goods, and reduces the damage rate of goods in the process of handling.

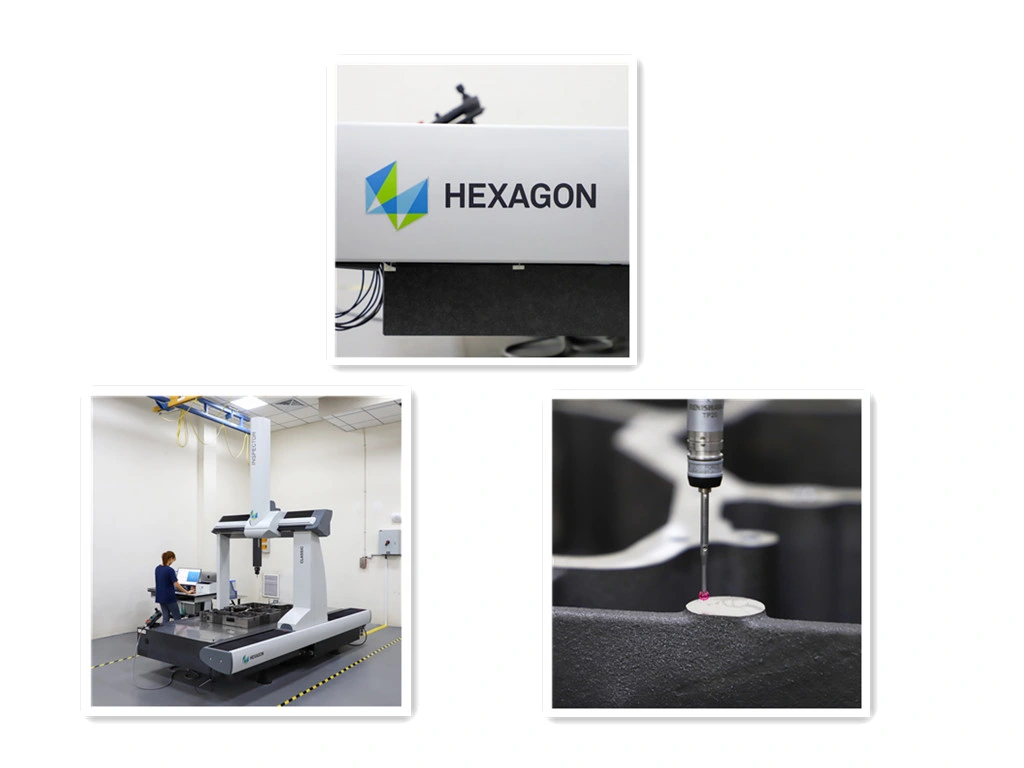

Quality Detection Workshop

Quality Detection Workshop

The company adopts advanced calibration and testing equipment to ensure the qualified rate of products produced in each process and strictly control the quality fluctuation, so as to ensure the product quality of the whole machine. Improve the production process through inspection, reduce the quality cost and enhance the comprehensive competitiveness of products.

Spraying Workshop

Spraying Workshop

Our spraying workshop adopts the same electrophoretic spraying technology as Tsudakoma, and is equipped with product automatic spraying production line and spraying robot independently developed by the company. The use of the new equipment can make the workpiece surface evenly and completely covered with a protective paint film, so as to ensure that there will be no incomplete paint film coverage and uneven paint film thickness. At the same time, the application of electrophoretic spraying technology significantly improves the anti rust and anti-corrosion ability of the workpiece. The service life of the loom is greatly improved.

Advanced Assembly Workshop

On the basis of the whole machine assembly line, the company introduced Siemens to intelligentize the loom assembly, and realized the "mobile people do not move" production mode, that is, the pulsating production mode. Through strict quality management, fine differentiation of assembly process flow, fastening connectors with special tools with fixed torque, and strict inspection of production facilities, the quality of the overall loom is improved.

Advantage of our factory

With CE certificate and ISO9001 certificate

we have our own R&D team

Good after sales service

Reliable manufacture

Exported to India,Bangladesh,Egypt,Indonesia

20 years manufacturing experience

we have high precision processing

Our company

Qingdao Haijia Machinery Co., Ltd. was established in 1995, since its establishment has been focused on the development of manufacturing water jet loom, is currently set research and development, manufacturing, sales and service as one of professional manufacturer of the largest water jet loom, is the participation of China water jet loom industry standards makers.Our company have our own R&D team,Devotes to the water jet, air jet loom research and development, creates a world famous brand textile enterprise Cutting-edge technology to build high-tech products, quality service helps us establish a world- class brand. Each month we can product 800 sets at least. Water jet loom sales for , the industry's firs 13 consecutive years, is China's textile machinery governing unit.23 years' experience, we can provide high grade service, and be your trusted textile machinery expert.

good surface quality, wide range of fabrics. Haijia heavy water jet loom has a number of invention patents, utility model patents. Such as reinforcement of beam design, from the high-speed operation of the air jet loom to maintain the stability of the characteristics, which makes the machine more stable, low defective rate and the quality of cloth. For example, weft design optimization, optimization of the beating angle, the beating is stable, smooth cloth. The optimization of the design is also reflected in the fabric of a wider range of adaptability.

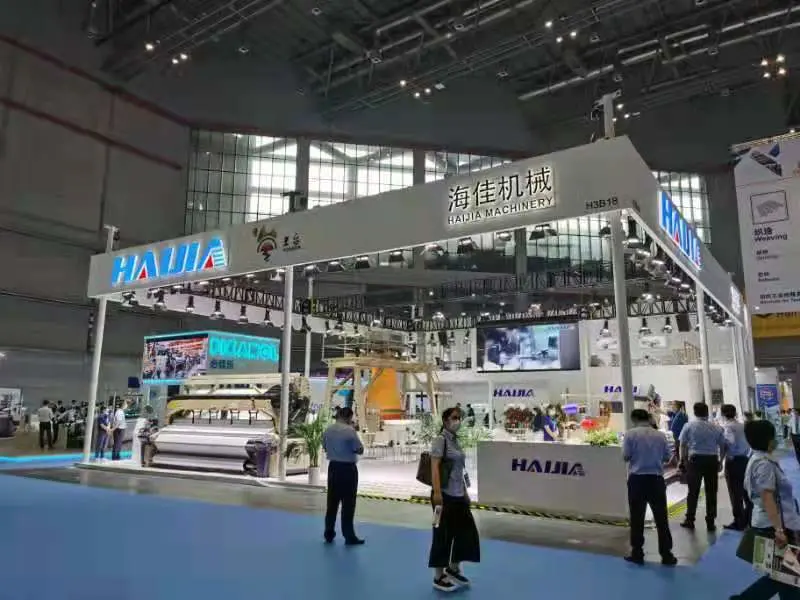

Exhibition Site

Why choose us

-Good performance and high quality machine,with good price.

-A talented engineers team releasing new model every years . Customized design is available;

-Overseas, we provide professional after-sales service engineers.

-Passed ISO9001,CE, SGS quality system;

-Abundant Customers from India, Bangladesh, Egypt, Indonesia and North Korea etc, highly satisfied with our product. Because of low cost, good performance and advanced model;

-Working with us, you can lower your cost for premium weaving loom, as we are factory direct and have the economy of scale.

FAQ

(1) Q: Are you a manufacturer or agency?

A:We are a comprehensive enterprise integrating independent r&d, manufacturing, final assembly, marketing and after-sale service, which can meet the needs of diversified customers and provide them with high-quality and affordable products and all-round services.

QINGDAO HAIJIA MACHINERY CO.,LTD

ADD:NO.39 HUANTAI DONG ROAD,WANGTAI TOWN HUANGDAO QINGDAO CITY CHINA

It's sales champion for 15 consecutive years in China Water Jet Loom's industry!

Haijia machine is China No. 1 brand in the textile field.

More than 80000 sets machine are running successfully.

21 years experience in manufacturing textiles.

Annual capacity of 8000 sets.

28% of the total global market, global one!

HW-3851# Cam Shedding Device Specification

| HW-3851# | ||

| No. | NAME | ORIGIN\TYPE\PERFORMACE DECRIPTION |

| 1 | Wall board | We adopts HJ-851special heavy enhanced, according to TSUDAKOMA Drawing,HT220-230 standard material,large CNC precision machining. |

| 2 | Gear in the large box | Adopt Taiwan Datong(TTG) gear, ultra-quite,wear-resistant,low vibration and high precision |

| 3 | Bearing in the large box | Bearing in the large box is swiden SKF, Bearing out of the large box made in japan. |

| 4 | Beating up shaft | Adopt special treatment of solid beating up shaft, centralized oil lubrication in the support sleeve, add in weft counterweight balance system (Haijia patent:201220718493.9), optimization of beating up angle, the beating up more powerful and stable, cloth smooth. |

| 5 | Slay | SUS304 stainless steel reinforced and polishing processing slay at the top brand in China, achieve cloth smooth. |

| 6 | Stripe | Tianqi stripe, For 102 double stick, strengthening take-up. |

| 7 | Plastic stocks | New type and high quality plastic stocks |

| 8 | Beam | A number of optimization design on the basis of TSUDAKOMA ZW-851, the beam before and after the five angle pipe, steel material supply, before and after the beam with thickened angle.Especially before the beam on Haijia, unique design, draws on the advantages of air jet loom beam, making solid beating up shaft is more stable. |

| 9 | Suction pipe | ∮76mm,thickness 6mm,sus304 stainless steel. |

| 10 | Cross beam | Heavy and lengthen treatment |

| 11 | Tension spring | ∮12mm |

| 12 | Panel | HJ-851 Special type |

| 13 | Let-off and take -up device | Mechanical or electronic |

| 14 | Temple bar,guide | HJ-851 Special type ,3mm stainless steel |

| 15 | Temple | Five ring three rows of fine needle puncture (0.3mm) under the pressure of Temple (made fine denier fabric cloth smooth) South Korea Renhe or Jilong brand. |

| 16 | Leno parts | Taiwan production assembly (slide seat:Stainless steel, low noise ear wire assembly, running smoothly, long service life). |

| 17 | Press roll | New press fabric service,press roll 40#,equal tension take-up |

| 18 | Main motor | The Haijia special power of 3.0KW red flag.Save electricity,start fast,low noise,little park,long life and other advantages(self-purchased Japan NACHI bearing) |

| 19 | Electronic control system | Xinliao Brand. |

| 20 | Measuring | Electronic measuring |

| 21 | Light detection weft | Light detection weft, plus plug signal amplifier |

| 22 | Code | Electronic code |

| 23 | Plunger | Shutai ceramic plunger(39/28 mm) |

| 24 | Spring | JAPAN AWA spring(∮10x∮150 mm) |

| 25 | Nozzle | Korea MDH 90/60 nozzle |

| 26 | One way valve | Japan AWA valve,up 8# down 9#. |

| 27 | Oil seal | Made in Taiwan |

| 28 | Cutter parts | Taiwan joint bearing,scissors,scissors spring ,improve efficiency. |

| 29 | Suction motor | Electronic suction motor |

| 30 | Stabilized tank | Double filter,bucket type. |

| 31 | Take heald level liner | American DuPont material production, wear, long service life. |

| 32 | Dobby or heald frame | Customer can match by themselves. |

| 33 | Painting | TSUDAKOMA yellow color, two times over the primer, topcoat, special paint production line, improve the anti rust effect. |

| 34 | The whole machine ofStainless steel screw | Taiwan dongming SUS304 stainless steel screw,not rust. |

| 35 | Waterproof device | Thickened waterproof curtain, TSUDAKOMA style transparent waterproof cover plate. |

| 36 | False twist spindle | Pull type |

| 37 | Weft stand | Double nozzle standard weft stand. |

| 38 | Swing degree | 95 Swing degree |

| 39 | Casting | Identify quality supplier, according to the standard drawings, guarantee the material and weight. |

The CNC Workshop in Our Factory Introduction

Advanced Manufacturing Workshop

The company is equipped with advanced CNC equipment, high-precision imported processing center, and adopts information management methods to achieve independent precision machining of precision parts of key parts of the loom. The processing accuracy of key parts and components reaches 0.01mm,greatly improving the whole machine Stability and startup efficiency.

Three Dimensions Warehouse

Three Dimensions Warehouse The company is equipped with an automated three-dimensional warehouse, which uses computers to accurately manage the goods information, reducing possible errors in the process of storing goods and improving work efficiency. At the same time, the three-dimensional automated warehouse realizes motorization in the transportation of goods in and out of the warehouse, which is safe and reliable in handling goods, and reduces the damage rate of goods in the process of handling.

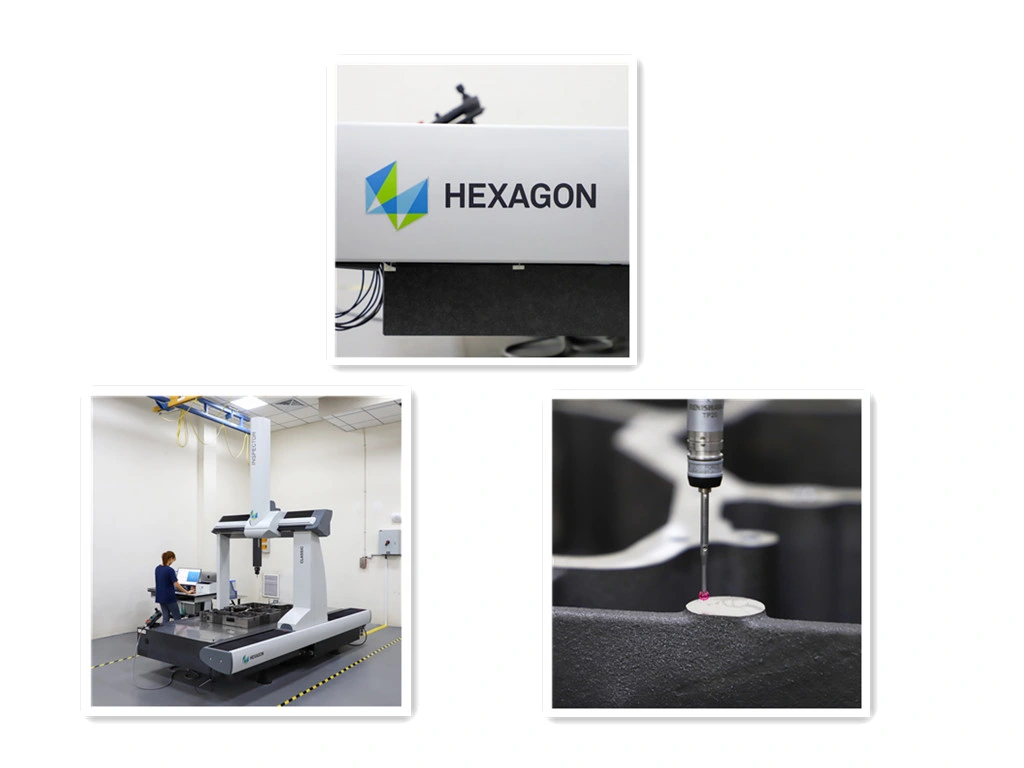

Quality Detection Workshop

Quality Detection Workshop The company adopts advanced calibration and testing equipment to ensure the qualified rate of products produced in each process and strictly control the quality fluctuation, so as to ensure the product quality of the whole machine. Improve the production process through inspection, reduce the quality cost and enhance the comprehensive competitiveness of products.

Spraying Workshop

Spraying Workshop Our spraying workshop adopts the same electrophoretic spraying technology as Tsudakoma, and is equipped with product automatic spraying production line and spraying robot independently developed by the company. The use of the new equipment can make the workpiece surface evenly and completely covered with a protective paint film, so as to ensure that there will be no incomplete paint film coverage and uneven paint film thickness. At the same time, the application of electrophoretic spraying technology significantly improves the anti rust and anti-corrosion ability of the workpiece. The service life of the loom is greatly improved.

Advanced Assembly Workshop

On the basis of the whole machine assembly line, the company introduced Siemens to intelligentize the loom assembly, and realized the "mobile people do not move" production mode, that is, the pulsating production mode. Through strict quality management, fine differentiation of assembly process flow, fastening connectors with special tools with fixed torque, and strict inspection of production facilities, the quality of the overall loom is improved.

Advantage of our factory

With CE certificate and ISO9001 certificate

we have our own R&D team

Good after sales service

Reliable manufacture

Exported to India,Bangladesh,Egypt,Indonesia

20 years manufacturing experience

we have high precision processing

Our company

Qingdao Haijia Machinery Co., Ltd. was established in 1995, since its establishment has been focused on the development of manufacturing water jet loom, is currently set research and development, manufacturing, sales and service as one of professional manufacturer of the largest water jet loom, is the participation of China water jet loom industry standards makers.Our company have our own R&D team,Devotes to the water jet, air jet loom research and development, creates a world famous brand textile enterprise Cutting-edge technology to build high-tech products, quality service helps us establish a world- class brand. Each month we can product 800 sets at least. Water jet loom sales for , the industry's firs 13 consecutive years, is China's textile machinery governing unit.23 years' experience, we can provide high grade service, and be your trusted textile machinery expert.

good surface quality, wide range of fabrics. Haijia heavy water jet loom has a number of invention patents, utility model patents. Such as reinforcement of beam design, from the high-speed operation of the air jet loom to maintain the stability of the characteristics, which makes the machine more stable, low defective rate and the quality of cloth. For example, weft design optimization, optimization of the beating angle, the beating is stable, smooth cloth. The optimization of the design is also reflected in the fabric of a wider range of adaptability.

Exhibition Site

Why choose us

-Good performance and high quality machine,with good price.

-A talented engineers team releasing new model every years . Customized design is available;

-Overseas, we provide professional after-sales service engineers.

-Passed ISO9001,CE, SGS quality system;

-Abundant Customers from India, Bangladesh, Egypt, Indonesia and North Korea etc, highly satisfied with our product. Because of low cost, good performance and advanced model;

-Working with us, you can lower your cost for premium weaving loom, as we are factory direct and have the economy of scale.

FAQ

(1) Q: Are you a manufacturer or agency?

A:We are a comprehensive enterprise integrating independent r&d, manufacturing, final assembly, marketing and after-sale service, which can meet the needs of diversified customers and provide them with high-quality and affordable products and all-round services.

(2) Q: How about the quality?

A: Electric control and major raw materials are provided by listed companies, and key components are developed by our own research and development team. We have high-precision processing centers such as mazak, hyundai dri WIR and HARTFORD, as well as high-precision testing instruments such as three-coordinate to guarantee the quality of our products.

(3) Q: How's the after-sale service?

A: We have more than 20 years of professional service engineers in textile machinery industry, if you need our first time to serve you.

QINGDAO HAIJIA MACHINERY CO.,LTD

ADD:NO.39 HUANTAI DONG ROAD,WANGTAI TOWN HUANGDAO QINGDAO CITY CHINA