Basic Info.

Model NO.

Z473

Classification

Fiberglass Geogrid

Material

Fiberglass

Size

Customized

Transport Package

Roll

Specification

customized

Trademark

Jubo

Origin

China

Product Description

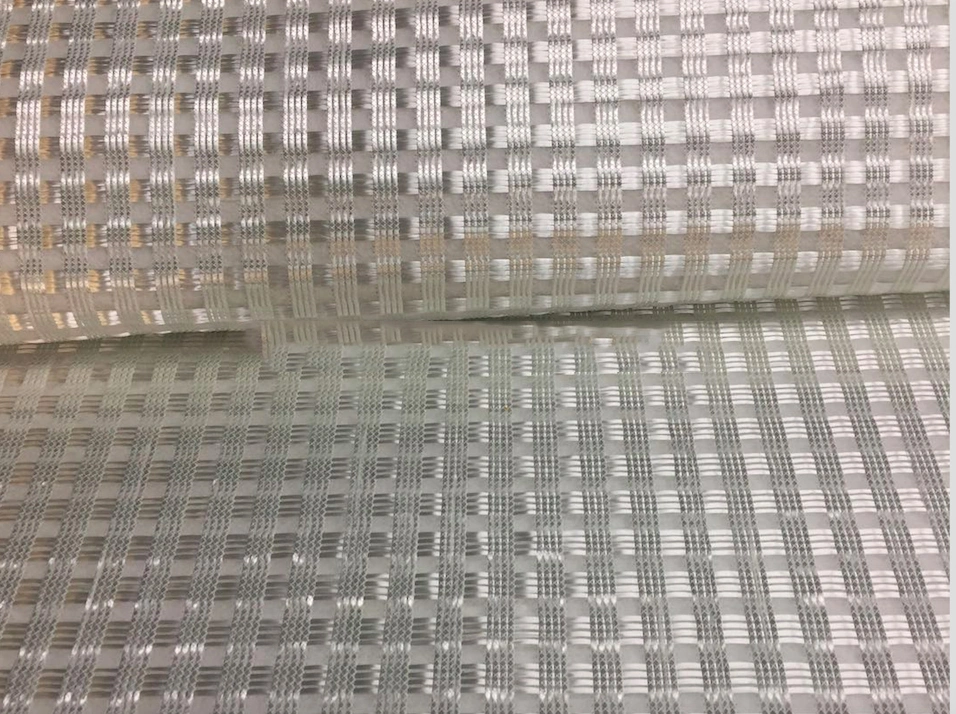

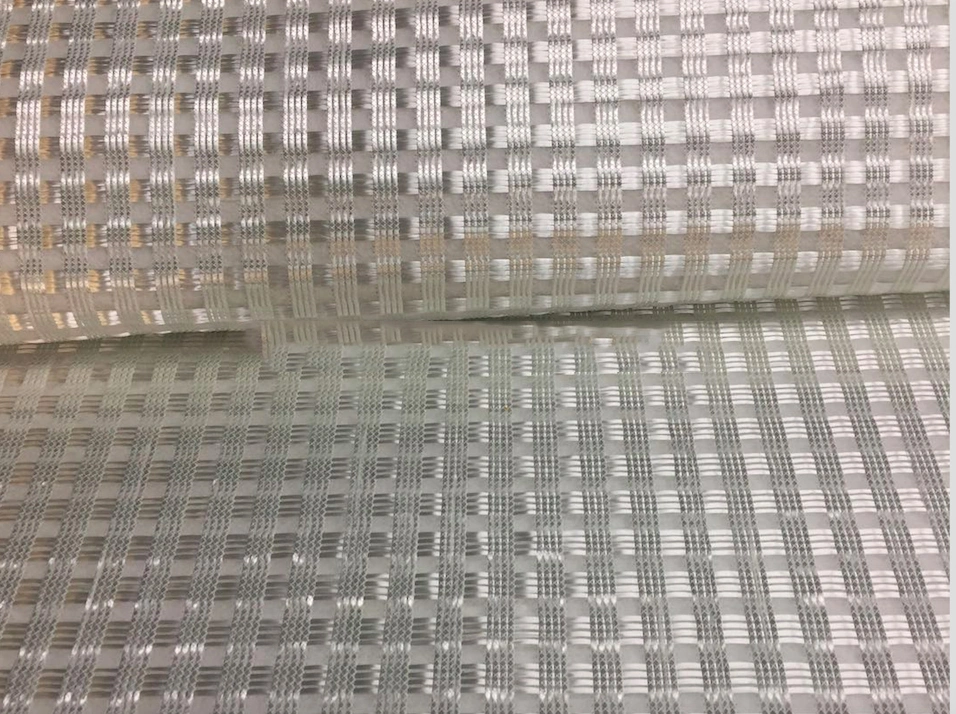

Fiberglass Warp-Knitting Geotextile Geocomposite for Aspahlt Cracking Reducing

Product Description

Product Description

Warp-knitting reinforced composite geotextile is a new composite geosynthetic material which is made of fiberglass yarns and geotextile. These two materials are sewed together by the warp-knitting machine.

1. A kind of planar mesh material using alkali-free fiberglass yarn as base body and then coated with high quality modified asphalt.

2. Warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant.

3. Coated with asphalt making full protection of the fiberglass matrix and greatly improving its wear and shear resistance.

4. Having a good performance in pavement strengthening, track cracking and solving difficulties of strengthening the bituminous pavement.

1. A kind of planar mesh material using alkali-free fiberglass yarn as base body and then coated with high quality modified asphalt.

2. Warp knitted with oriental structure which gives full play of yarn strength and improves its mechanical property to make the product high tensile, tearing and creep-resistant.

3. Coated with asphalt making full protection of the fiberglass matrix and greatly improving its wear and shear resistance.

4. Having a good performance in pavement strengthening, track cracking and solving difficulties of strengthening the bituminous pavement.

Procuct Features

2.To prevent and delay the crack reflection: it has low elongation and high tensile strength, and effectively clears the stress at the joint or crack position, reduce the crack expansion and reflection in the pavement, and postpone crack reflection.

1.New road and renovation project.

2.Asphalt overlay on the old cement concrete road surface

3.Repair of asphalt pavements cracks and old asphalt road

4.Reinforcing the layer of airport runway, bridge, playground

2.Asphalt overlay on the old cement concrete road surface

3.Repair of asphalt pavements cracks and old asphalt road

4.Reinforcing the layer of airport runway, bridge, playground

| Project/Size | HS30-30 | HS40-40 | HS50-50 | HS60-60 | HS80-80 | HS100-100 | HS120-120 | |

| Elongation rate % | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | |

| Tensile strength(KN/M) | Vertical | 30 | 40 | 50 | 60 | 80 | 100 | 120 |

| Horizontal | 30 | 40 | 50 | 60 | 80 | 100 | 120 | |

| Tearing intensity(KN/M) | 0.08-0.42 | |||||||

| Complex style | Complex warp knitting reinforcement | |||||||

| Penetrating parameter | K x(10-1-10-3)K=1.0-9.9 | |||||||

| Equation mesh size | 0.07-0.2 | |||||||

| Width(M) | 1-6 | |||||||

| Special specifications can be customized as required | ||||||||

Related product

Contact us

FAQ

Q: Are you trading company or manufacturer ?

A: We are factory.

Q:Is the quality of your products stable?

The company has a complete QC system, and each batch of products will be sampled and the samples will be kept for 5 years.

Q:Can you do OEM?

A:Yes, of course. We can produce the products as per your request.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 10-15 days if the goods are not in stock, it is according to quantity.

Q: What is your terms of payment ?

A: Payment<=5000USD, 100% in advance. Payment>=5000USD, 30% T/T in advance,balance before shipment. If you have another question, please feel free to contact us at any time.