Basic Info.

Product Description

Incorporated surface veil offers reduced print-through, Stitch free for improved visual appearance

Very good drapability, High-Flow version with faster flow rate

Cut mat has tidy edges, clean and free of fraying with no fiber falling out

Flexible range of applications and individually adaptable

Clean splicing avoids thick overlaps of composite material, Better blister performance can remove the need for added barrier coat

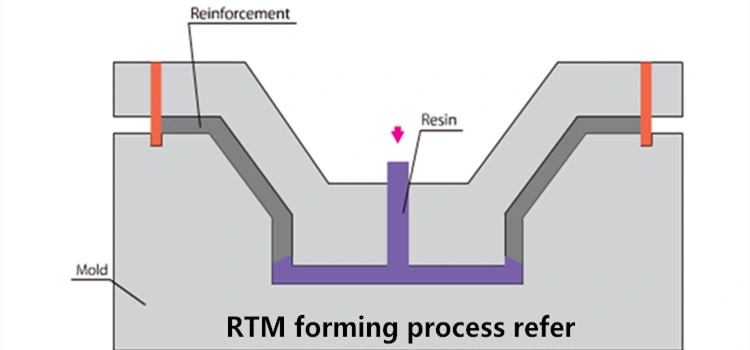

Product Type: ECR glass fiber PP core combination mat ZHONGJIE Code: EMNM600/250/600 Unit weight: 1450g/m2 (+/-5%) Raw material: Fiberglass assembled roving, PP core material, Polyester yarn Technics: ECR glass fiber PP core combination mat is made of chopped roving combined PP core layer and plus the chopped strands, then stitched together by polyester yarn as sandwich structure Chopped density: 600/600 g/m2 (top/bottom layer) PP core density 250g/m2 (+/-5%) Polyetser yarn: 8g/m2 (+/-5%) Roll packing width: Normal size is 1270mm, tape size available from 200mm to 2600mm, depends on customer's real needs Mositure content: ≤0.15% Wet speed ≤45/S Sizing/Coupling agent: Silane Combustible Content: 0.4 - 0.8% Usage process: RTM, LRTM, Vaccum infusion,Compression molding etc; Compatible resins: Polyester resin, Vinyl resin, Epoxy resin, Phenolic resin etc; Application: Wind nacelle, Boats & Yachts, FRP vessel/Cover, Auto parts, Waterpark equipments etc;

Catalog refer:

| Product code | Specification (Layer weight (g/m²) | Standard roll width (mm) | Surface fleece available | ||||

| Chopped strands | PP | Chopped strands | Stitch yarn | Unit weight (g/m2) | |||

| EMNM300/180/300 | 300 | 180 | 300 | 8 | 788 | 1270/2540 | Polyester tissue |

| EMNM450/180/450 | 450 | 180 | 450 | 8 | 1088 | 1270/2540 | Polyester tissue |

| EMNM600/180/600 | 600 | 180 | 600 | 8 | 1388 | 1270/2540 | Polyester tissue |

| EMNM300/250/300 | 300 | 250 | 300 | 9 | 859 | 1270/2540 | Polyester tissue |

| EMNM450/250/450 | 450 | 250 | 450 | 9 | 1159 | 1270/2540 | Polyester tissue |

| EMNM600/250/600 | 600 | 250 | 600 | 9 | 1459 | 1270/2540 | Polyester tissue |

| EMNM750/250/750 | 750 | 250 | 750 | 9 | 1759 | 1270/2540 | Polyester tissue |

Factory description:

* Best fiberglass roving and chopped strand supply in China like JUSHI, CTG, CPIC, Shandong fiberglass keeps our products excellent performance and steady in quality

* Well-known in FRP forming process and application keeps our products more outstanding and humanized

* Professional and experienced staff makes our production line more efficient and contineous improvement

* Good management makes our product more competitive in trunout and prices

* More than 45 sets production lines with kinds of machines makes us great production capacity

Applications refer:

ECR glass fiber PP core combination mat widely used in RTM applicated to Auto parts, Railways, Wind energy, Yachts building, Waste-water treatment, Waterpart equipments etc;

Exhibition notice (We will be there waiting for you):

* JEC Shanghai expo -- Sep., 2018

* India composites show -- Dec., 2018

* JEC Paris expo -- March., 2019

FAQ:

Q: Are you a factory or trading company?

A: We are a professional fiberglass fabrics and mats manufacturer from 2008, doing kinds of fierglass composites.

Q:Where is your factory located? How can I visit there?

A: Our factory located in Tianning district, Changzhou city, Jiangsu province. About 1.5-2 hours from Shanghai(air port and train station), All our clients, from home or abroad, are warmly welcome to visit us!

Q: What is your annual turn over?

A: In 2017, yearly output more than 18,000 tons, and turnover more than 150,000,000 RMB.

Q: How can you guarantee your quality?

A: Quality is priority. Zhongjie people always attach great importance to quality con trolling from the very beginning to the very end

1. All raw materials we used are from very famous, quality ensured factory like Jushi, CTG, Shandong Fiberglass...

2. Skillful workers care every details in production, packing, transporting. To make sure costomers recived our best made.

3. Quality control department with experienced professers, engineers who from authroized FRP Universities, Reaseach institutes...etc;

Q: What is your lead time?

A: Usually in 7-10 days for productions and stock always about 3-5 days.