Basic Info.

Model NO.

DBM1708

Csm Area Weight

275GSM

Roving in +45 Degree

300GSM

Roving in -45 Degree

300GSM

Glass Type

E Glass

Transport Package

Carton and Pallet

Specification

DBM1708

Trademark

utek

Origin

China

HS Code

7019

Production Capacity

100ton/Month

Product Description

DBM1708 Biaxial +/-45 Fiberglass Fabric is made up of 17 ounces of Strands ,stitched at a 45° angle, and 8 ounces of chopped strand mat backing. for a total of 25 ounces per square yard. It consists of two layers that are stitched together, they are laying at a 45° angle to each other. 1708 is E-glass Biaxial (+/-45) with a 3/4 ounce chopped strand mat backing.

It also gives you the ability to lay the fibers in the direction you want, and has excellent conforming qualities(it goes around corners well) .

The fabric and the mat work together to make a very strong end product.

Used where strong stiff and smooth laminate with equal strength in two directions is desired. Good wet out, and quick thickness build up. Excellent resin to reinforcement ratio.

Packing & Storage:

Each roll is put into a polyethylene bag,fastened the bag entrance and packed into a suitable carton upon to customer's request,this product could be shipped either with carton packaging only or with pallet packaging,the products could be put on the pallets and fastened with packing straps and shrink film.

This product should be stocked in dry and cool places.The best condition is with temperature between 5 ºC and 35 ºC,with a relative humidity between 35% and 65%.Please keep the product in its original packaging before use,avoiding moisture.

Packing:

Close Look at Product:

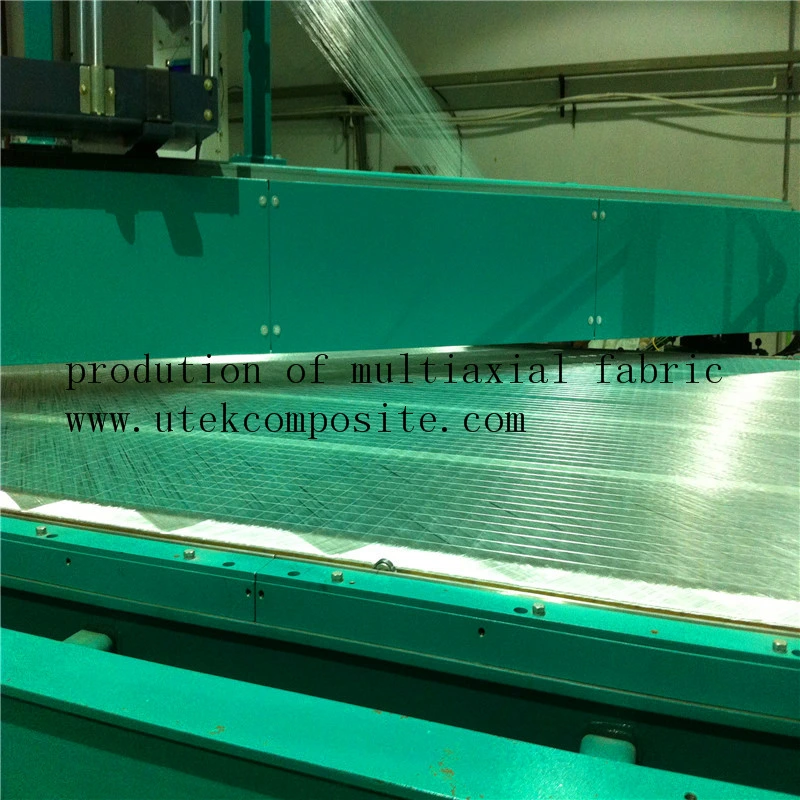

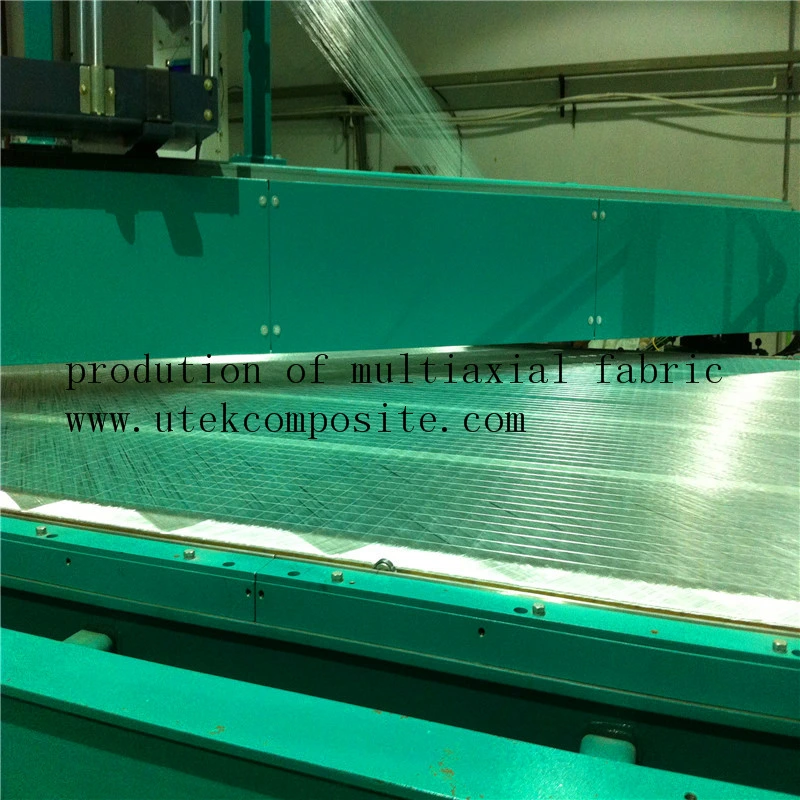

Production Site:

Technical Data:

Give us a chance, and we' ll return you with satisfaction.

It also gives you the ability to lay the fibers in the direction you want, and has excellent conforming qualities(it goes around corners well) .

The fabric and the mat work together to make a very strong end product.

Used where strong stiff and smooth laminate with equal strength in two directions is desired. Good wet out, and quick thickness build up. Excellent resin to reinforcement ratio.

Packing & Storage:

Each roll is put into a polyethylene bag,fastened the bag entrance and packed into a suitable carton upon to customer's request,this product could be shipped either with carton packaging only or with pallet packaging,the products could be put on the pallets and fastened with packing straps and shrink film.

This product should be stocked in dry and cool places.The best condition is with temperature between 5 ºC and 35 ºC,with a relative humidity between 35% and 65%.Please keep the product in its original packaging before use,avoiding moisture.

Packing:

Close Look at Product:

Production Site:

Technical Data:

| Item | 0° g/m2 | +45° g/m2 | -45° g/m2 | 90° g/m2 | Mat g/m2 | Total g/m2 |

| E-BX300 | 150 | 150 | 300 | |||

| E-BX600 | 300 | 300 | 600 | |||

| E-BX800 | 400 | 400 | 800 | |||

| E-BXM 825 | 300 | 300 | 225 | 825 | ||

| E-DBM875 | 300 | 300 | 275 | 875 | ||

| E-TX900 | 300 | 300 | 300 | 900 | ||

| E-TLX900 | 225 | 225 | 450 | 900 | ||

| E-QX1200 | 300 | 300 | 300 | 300 | 1200 |

Give us a chance, and we' ll return you with satisfaction.