Basic Info.

Model NO.

PW-PA66GF25

Fiber Type

Gfrp

Applied

PA Thermal Break Strips

Raw Material

PA66+Fiberglass

Density

1.25~1.35 g/cm3

UV Resistant

Yes

Transport Package

Woven Bags

Specification

25kg/bag

Trademark

Polywell

Origin

Zhangjiagang, China

HS Code

3908101190

Production Capacity

20 Tons Per Day

Product Description

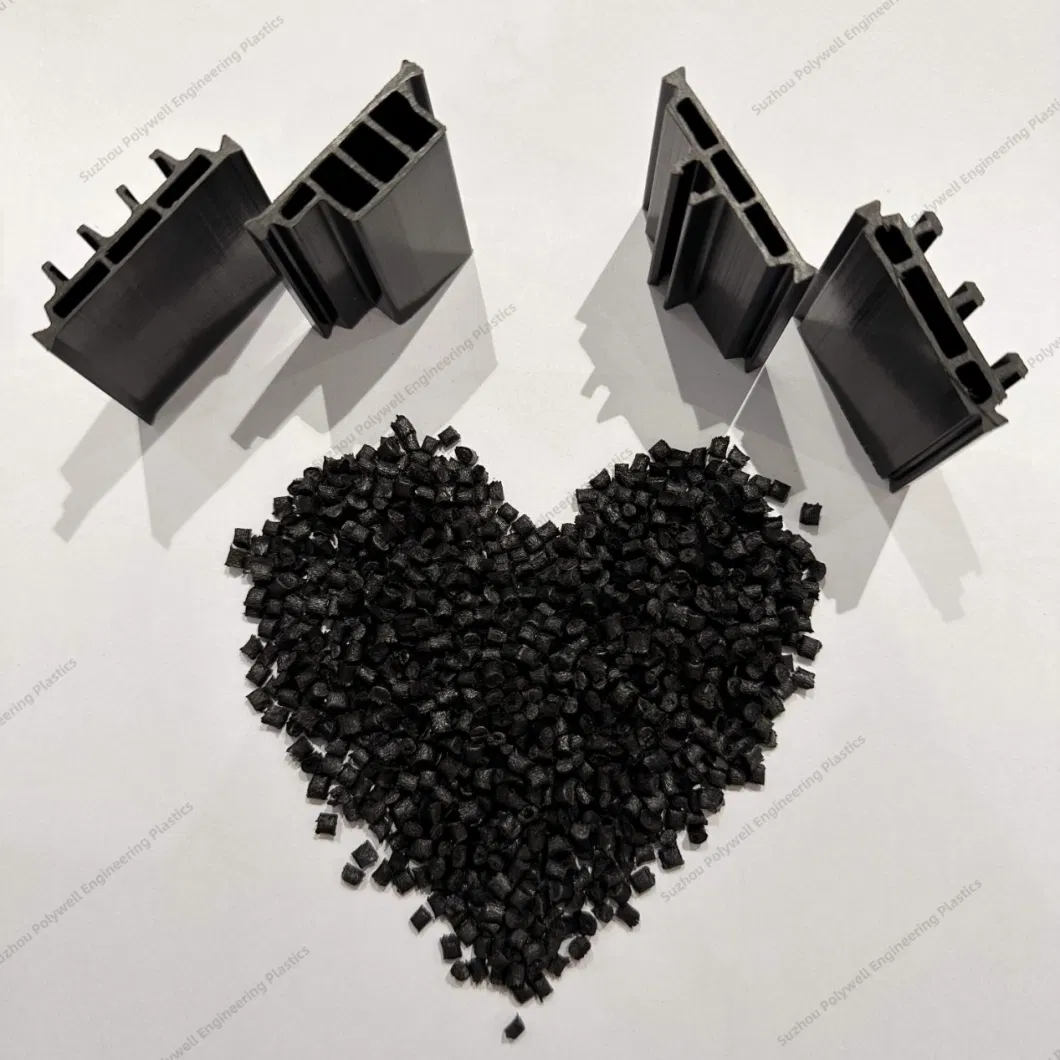

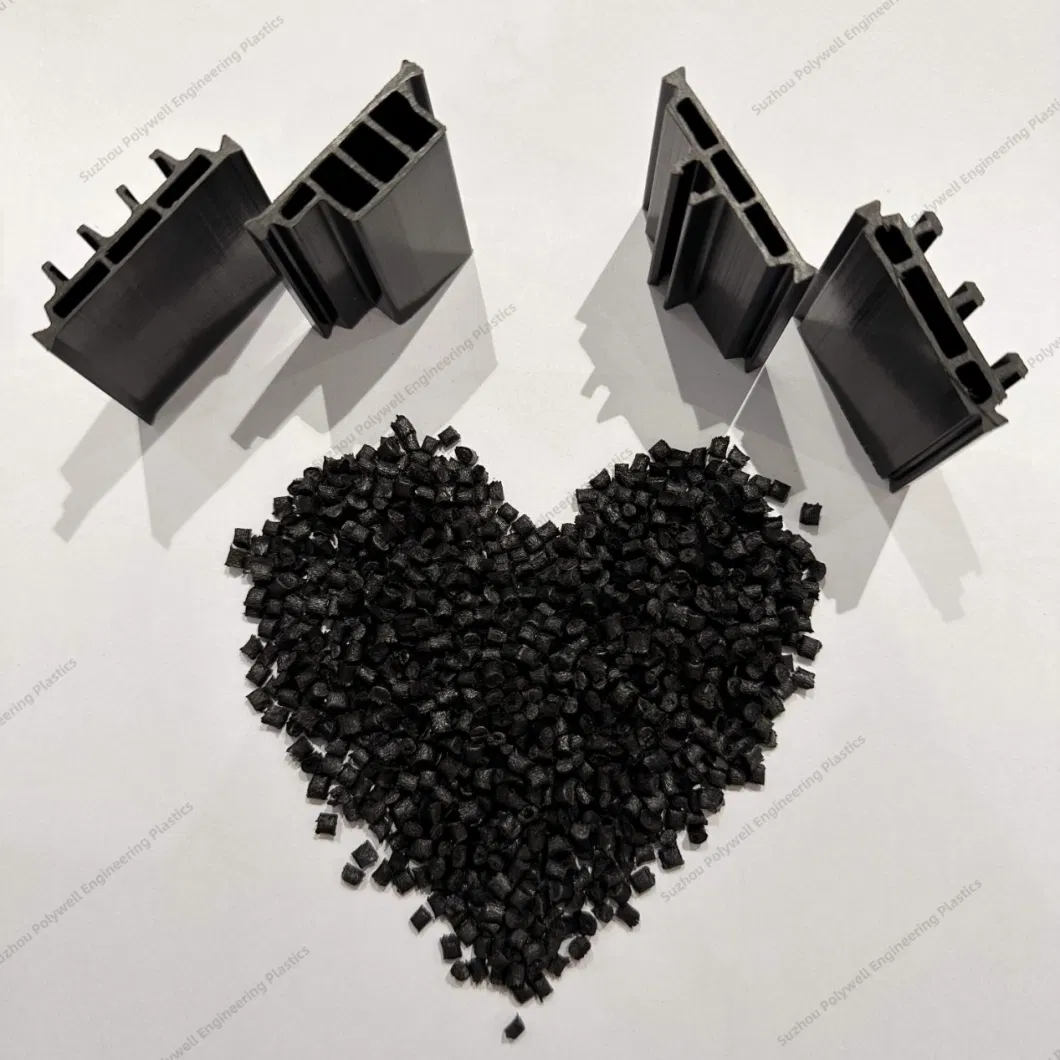

Customized Fomular PA66 GF25 Glass Fiber Toughened Granules Polyamide Pellets Nylon Compound

Product Introduction:

-Nylon/PA66 granules reinforced by fiberglass. The performance of final products of this raw material were in line with the national standard.

-The product is based on PA66 resin as basic, add glass fiber, efficient flame retardants and various additives, formed by twin-screw extrusion blending.

Polywell PA66 Granules Performance Table

3.The specifications marked with "a" only applies to I-shape strip otherwise, the specifications concluded between supplier and buyer through consultation, shall be written in contract or purchase order.

About color:

The color of our products is black, but we also can customize according to customers' requirements.

Application:

Widely used in machinery, instrumentation, automotive parts, electrical and electronics, railways, household appliances, telecommunications, textile, sports and leisure goods, pipes and precision engineering products.

Packaging & Delivery:

Packaging details: 25kg/bag

Delivery details: Shipped in 5-7 working days after payment

Our Company:

Related Products we can provide:

Please feel free to contact us if you have any questions

Product Introduction:

-Nylon/PA66 granules reinforced by fiberglass. The performance of final products of this raw material were in line with the national standard.

-The product is based on PA66 resin as basic, add glass fiber, efficient flame retardants and various additives, formed by twin-screw extrusion blending.

Advantage:

- High mechanical strength

- High toughness

- High softening point

- Good wear resistance

- Self-lubrication

- Long-term work at higher temperatures

- It has high CTI value , excellent electrical insulation, low smoke and low toxicity characteristics.

Details of related standard:

- GB/T 23615.1-2009 Accessorial material for architectural aluminum alloy profiles -- Part 1: Thermal barrier strip of polyamide

- EN 14024-2004 Metal profiles with thermal barrier -- Mechanical performance Requirement, proof and tests for assessment

- YS/T 437-2008 Aluminium profiles moment of inertia calculation methods and computing software requirements

- JG/T 174-2005 Thermal barrier strips for construction industry

- GB 5237.6 -2012 Wrought aluminium alloy extruded profiles for architecture -- Part 6: Thermal barrier profiles

- GB/T 8478-2008 Aluminium windows and doors

- GB/T 8484-2008 Graduation and test for thermal insulating properties of doors and windows

- JG 175-2011 Insulating aluminum alloy profiles with thermal barrier for buildings

Polywell PA66 Granules Performance Table

| NO. | Item | Unit | GB/T 23615.1-2009 | PW-Technical specification |

| Material Properties | ||||

| 1 | Density | g/cm3 | 1.3±0.05 | 1.28-1.35 |

| 2 | Linear expansion coefficient | K-1 | (2.3-3.5)×10-5 | (2.3-3.5)×10-5 |

| 3 | Vicat softening temperature | ºC | ≥230ºC | ≥233ºC |

| 4 | Melting point | ºC | ≥240 | ≥240 |

| 5 | Testing for tensile cracks | - | No cracks | No cracks |

| 6 | Shore hardness | - | 80±5 | 80-85 |

| 7 | Impact strength(Unnotched) | KJ/m2 | ≥35 | ≥38 |

| 8 | Tensile strength(longitudinal) | MPa | ≥80a | ≥82a |

| 9 | Elasticity modulus | MPa | ≥4500 | ≥4550 |

| 10 | Elongation at break | % | ≥2.5 | ≥2.6 |

| 11 | Tensile strength(transverse) | MPa | ≥70a | ≥70a |

| 12 | High temperature tensile strength(transverse) | MPa | ≥45a | ≥47a |

| 13 | Low temperature tensile strength(transverse) | MPa | ≥80a | ≥81a |

| 14 | Water resistance tensile strength(transverse) | MPa | ≥35a | ≥35a |

| 15 | Aging resistance tensile strength(transverse) | MPa | ≥50a | ≥50a |

1.Sample water content less than 0.2% by weight.

2.Norm laboratory condition:(23±2)ºC and (50±10)% relative humidity.3.The specifications marked with "a" only applies to I-shape strip otherwise, the specifications concluded between supplier and buyer through consultation, shall be written in contract or purchase order.

About color:

The color of our products is black, but we also can customize according to customers' requirements.

Application:

Widely used in machinery, instrumentation, automotive parts, electrical and electronics, railways, household appliances, telecommunications, textile, sports and leisure goods, pipes and precision engineering products.

Packaging & Delivery:

Packaging details: 25kg/bag

Delivery details: Shipped in 5-7 working days after payment

Our Company:

Related Products we can provide:

| Thermal Break Strip Extruding Machine | Thermal Break Strip | Granulator Machine |

Please feel free to contact us if you have any questions

Address: Jinfeng Town, Zhangjiagang City, Jiangsu Province, China