Basic Info.

Model NO.

ZD3000-V

Folding Type

Double Parallel Fold

Paper Inputting Type

Continuous Feeding

Type

Paper Folding Machine

Computerized

Computerized

Automatic Grade

Automatic

Folding Mechanism

Folding Buckle

Structure

Folding

Purpose

Connect with Irony Machine

Transport Package

Wooden Case

Specification

ISO9001

Trademark

Flying Fish

Origin

Shanghai China

HS Code

8451500000

Production Capacity

5000 Set /Year

Packaging & Delivery

Package Size

5159.00cm * 2102.00cm * 1305.00cm

Package Gross Weight

1230.000kg

Product Description

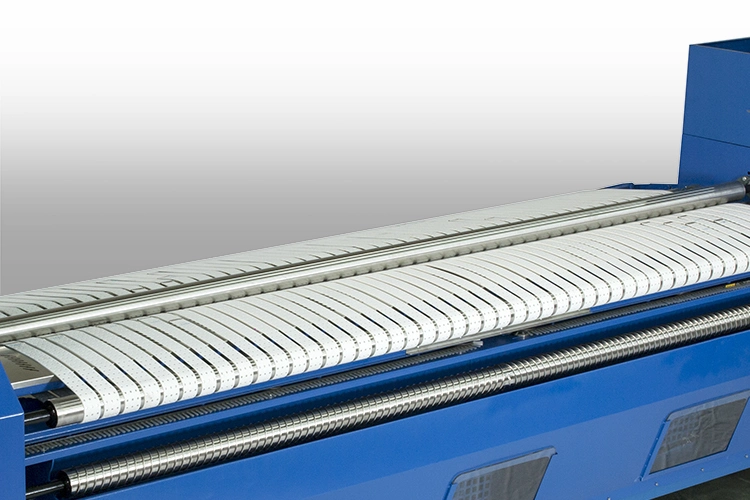

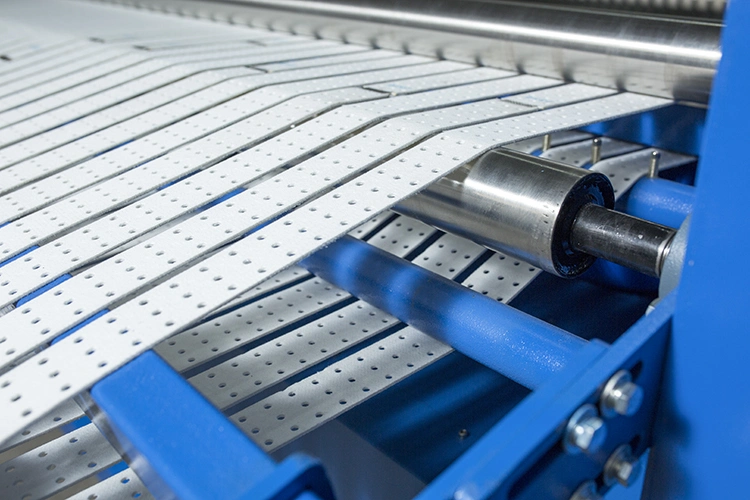

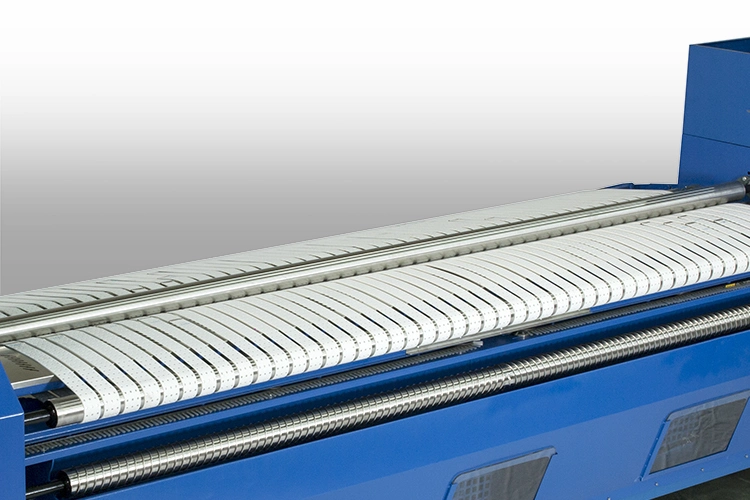

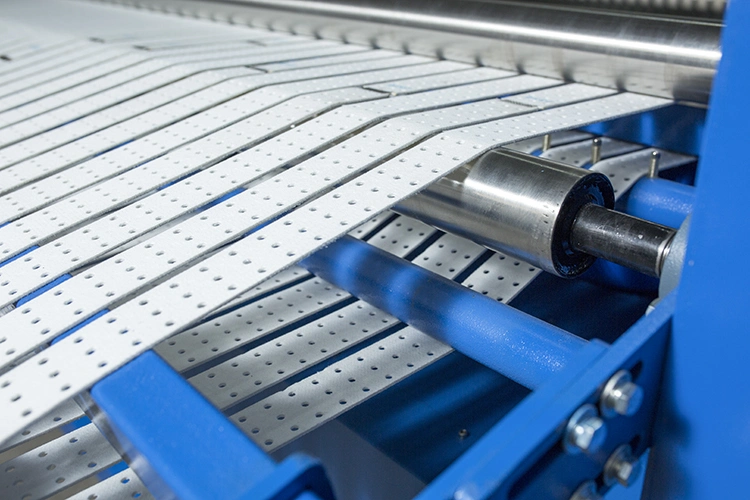

Full Automatic Towel Folding Machine

1. Auto control with big LED screen and multi-language interface.

2. The sizes of towels can be detected and the folding width can be adjusted by the sensor. Lateral folding is done with relative folding blade.

3. The length of towels can be measured with the coder on the revolving shaft and the folding mode can be automatically decided. The first cross fold is done via running in both directions and blowing system.

4. The structure innovatively designed is adaptable to different thickness of towels and ensure good result of folding and enter the second fold smoothly. 5. The second cross fold is done also via motor running in both directions and blowing system with adding the adjustable tilting degree of the conveying terrace so that the folding result is ensured.

6. Output postioned accurately. Auto counter for stacking. Fast respond. Short work cycle.

7. Conbined with international advanced techology on the fields fo computer, communication and controlling, the multi-intelligent controlling system is designed specially for TOWEL folding, which can be surveilled and controlled via net, and has the functions of character istic embedded software and comprehensive intelligent surveillance

8. Programmable. Auto and manual modes available.

9. An auto retractor device is installed at the end of stack, which can control the transfer belts stretch out and retract without change of direction so as to smoothly transport stacked towel of mul-piece to the next transfer belts.

As an 13 years old exporter-manufacturer, we always mass produced, be normal and accurate. Each machine

Must be tested for 3 days before delivery to make sure all parts working excellent.

Regarding service, every sales must work half a year in workshop firstly, to gained

Good technical knowledge to help our clients.

Any questions at any time, just feel free to call us.

Contact Person: Liz

We are here doing our best to establish good business relationship with you.

*Customer's satisfaction is the biggest Treasure of us*

1. Auto control with big LED screen and multi-language interface.

2. The sizes of towels can be detected and the folding width can be adjusted by the sensor. Lateral folding is done with relative folding blade.

3. The length of towels can be measured with the coder on the revolving shaft and the folding mode can be automatically decided. The first cross fold is done via running in both directions and blowing system.

4. The structure innovatively designed is adaptable to different thickness of towels and ensure good result of folding and enter the second fold smoothly. 5. The second cross fold is done also via motor running in both directions and blowing system with adding the adjustable tilting degree of the conveying terrace so that the folding result is ensured.

6. Output postioned accurately. Auto counter for stacking. Fast respond. Short work cycle.

7. Conbined with international advanced techology on the fields fo computer, communication and controlling, the multi-intelligent controlling system is designed specially for TOWEL folding, which can be surveilled and controlled via net, and has the functions of character istic embedded software and comprehensive intelligent surveillance

8. Programmable. Auto and manual modes available.

9. An auto retractor device is installed at the end of stack, which can control the transfer belts stretch out and retract without change of direction so as to smoothly transport stacked towel of mul-piece to the next transfer belts.

As an 13 years old exporter-manufacturer, we always mass produced, be normal and accurate. Each machine

Must be tested for 3 days before delivery to make sure all parts working excellent.

Regarding service, every sales must work half a year in workshop firstly, to gained

Good technical knowledge to help our clients.

Any questions at any time, just feel free to call us.

Contact Person: Liz

We are here doing our best to establish good business relationship with you.

*Customer's satisfaction is the biggest Treasure of us*

| Max size before folding | mm | 1200x1920 |

| Max size after folding | mm | 600x650 |

| Air consumption | L/min | 200 |

| Compressed air connection dia | mm | Φ12 |

| Rated motor power | KW | 3 |

| Power consumption | KW.h/h | 2 |

| Cycle time | second | 3-7 |

| Capacity | pcs/h | 800-1200 |

| Air Pressure | mpa | 0.5-0.7 |

| Dimension | mm | 2102x1305x5159 |

| Total Weight | kg | 1200 |