Basic Info.

Model NO.

LKT006

Pattern

Braided or Twisted

Type

Braided

Coarseness

Fine Yarn

Structure

Multifilament Yarn

Application

Aerospace/Climbing/Industry

Breaking Strengh

1.2kn-400kn(up to Size)

Size

Customized

Shape

Flat,Aramid Sleeve,Square,Round

Rope Type

Braided Rope

Color

Yellow, White, Black, etc

Working Temperature

0-500ºC

Elongation at Break

3%

Place of Origin

China

Raw Material Origin

USA, Japan

Roll Length

250 M

Lead Time

3 Days

Sample Time

1-3 Days

Transport Package

Carton

Specification

5.5x5.5, 13x3.5, 12x4, 8x4, 6x6, etc

Trademark

Lekker

Origin

Luoyang, China

HS Code

54025990

Production Capacity

1000000m Per Month

Product Description

Key Features

High Toughness (Work-To-Break)

High Tensile Strength at Low Weight,Lower compression strength

Low Elongation to Break, High Modulus (Structural Rigidity) Elongation at break

High Cut Resistance

Low Electrical Conductivity

Low Thermal Shrinkage

Flame Resistant, Self-Extinguishing Critical Temperature 400.F Excellent Dimensional Stability

Relatively poor compression strength

Durability

Wide Application:

It is mainly used for high temperature operation, special ship, electrical engineering, marine operations, various types of slings, suspension, research and other fields.

Kevlar rope uses aramid /kevlar fiber as raw material with advantages of high temperature resistance, wear resistance, cutting resistance, high strength, no scratch glass, etc.The glass is heated by a furnace at a temperature of 200-500 ° C. and then cooled by a grill. The glass is exposed to cold metal rollers due to a large temperature difference. The aramid roller rope spirally cools the roller of the furnace, Metal liner between the formation of padding, the glass can not be exposed to low temperature metal roller, glass to avoid scratches, collisions, cold burst. Thereby improving the yield of steel.

Basic Index:

Common sizes:

Product Show:

High Toughness (Work-To-Break)

High Tensile Strength at Low Weight,Lower compression strength

Low Elongation to Break, High Modulus (Structural Rigidity) Elongation at break

High Cut Resistance

Low Electrical Conductivity

Low Thermal Shrinkage

Flame Resistant, Self-Extinguishing Critical Temperature 400.F Excellent Dimensional Stability

Relatively poor compression strength

Durability

Wide Application:

It is mainly used for high temperature operation, special ship, electrical engineering, marine operations, various types of slings, suspension, research and other fields.

Kevlar rope uses aramid /kevlar fiber as raw material with advantages of high temperature resistance, wear resistance, cutting resistance, high strength, no scratch glass, etc.The glass is heated by a furnace at a temperature of 200-500 ° C. and then cooled by a grill. The glass is exposed to cold metal rollers due to a large temperature difference. The aramid roller rope spirally cools the roller of the furnace, Metal liner between the formation of padding, the glass can not be exposed to low temperature metal roller, glass to avoid scratches, collisions, cold burst. Thereby improving the yield of steel.

Basic Index:

| Function | Transport Glass |

| Color | Yellow or White |

| Application | Quenching section of glass tempering furnace |

| shape | square, or round |

| Composition | 100% kevlar (poly aramid) |

| Breaking strength | 353N |

| Appearance | Rope |

| Color | Yellow |

| Character | High temperature resistance (≥500ºC) |

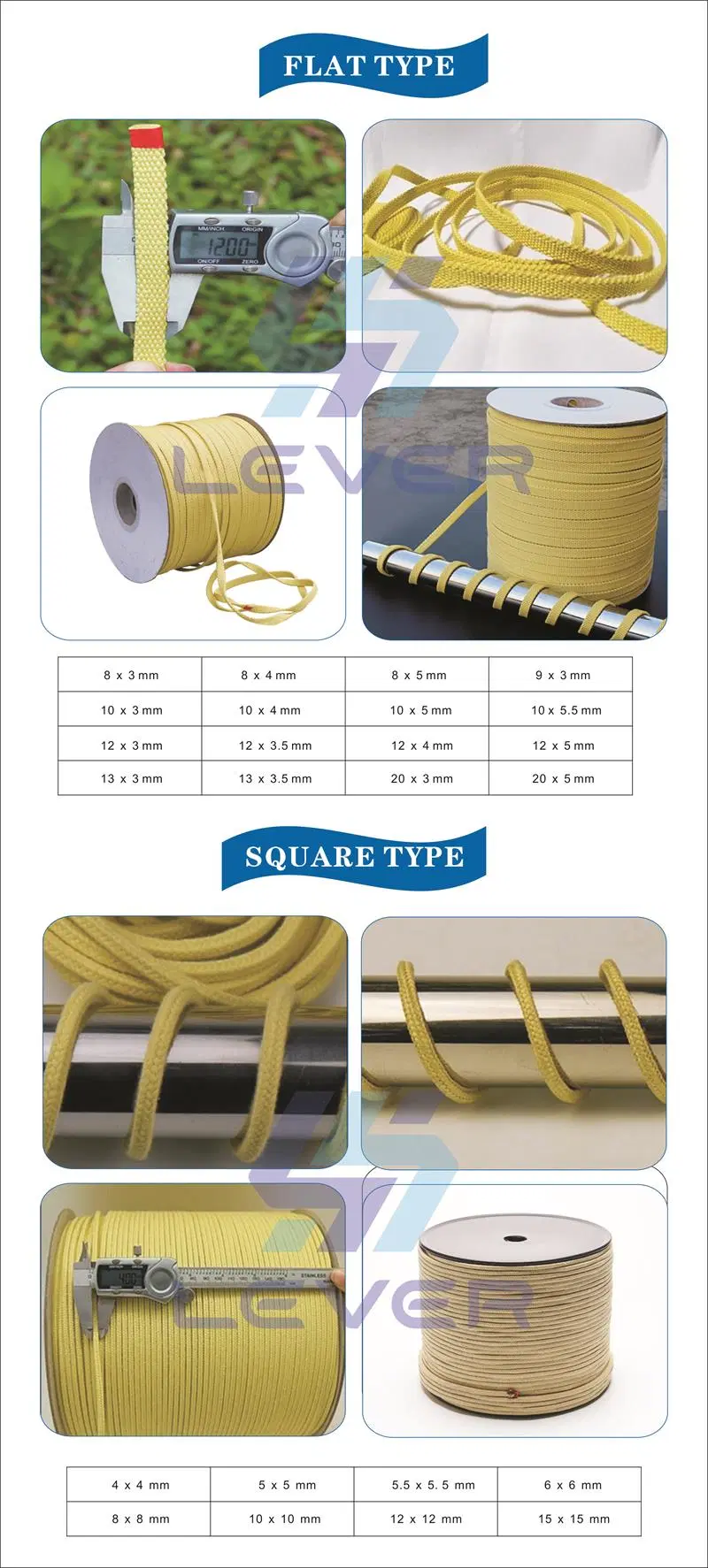

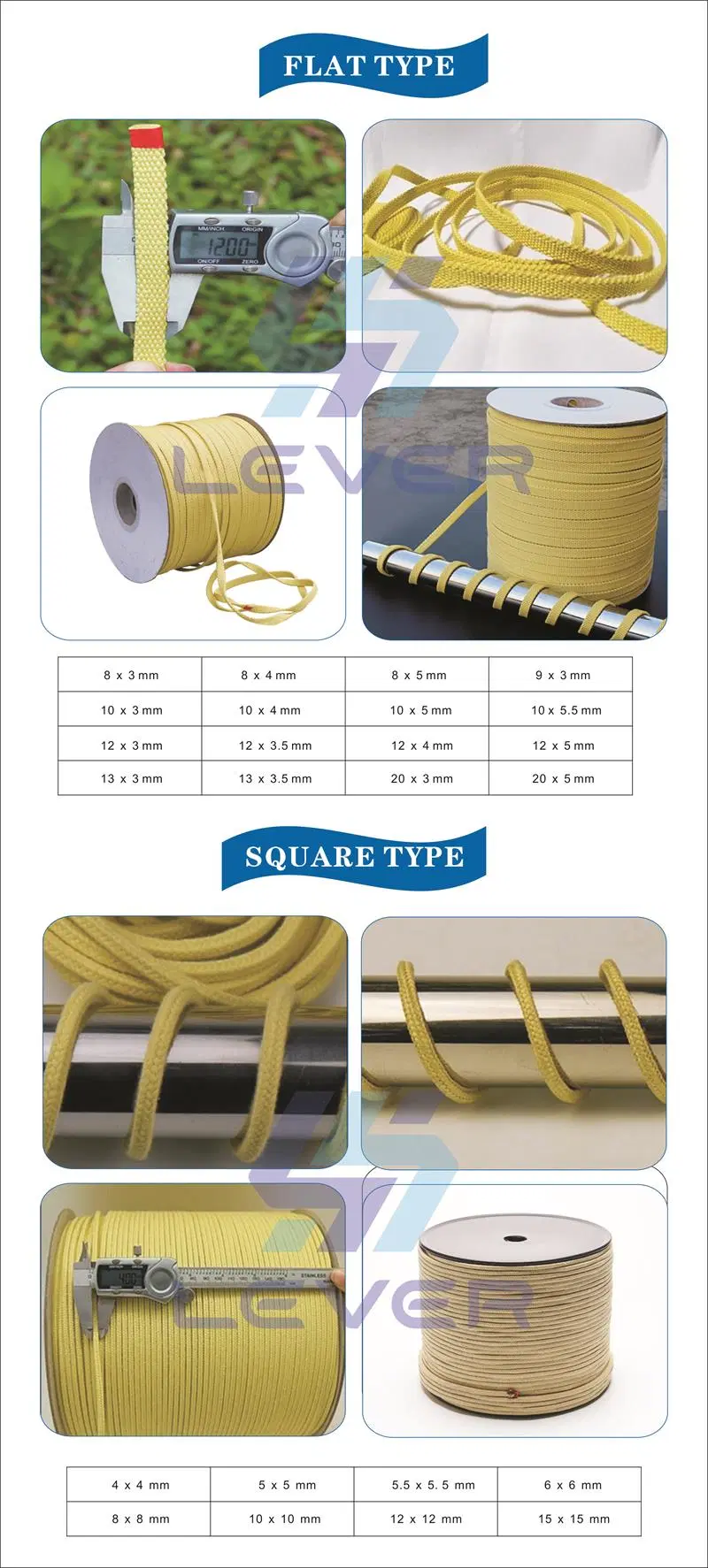

Common sizes:

| Flat Type Kevlar Aramid Rope | ||

| 8. x 3 mm | 12 x 3 mm | |

| 8 x 4 mm | 12 x 3.5 mm | |

| 8 x 5 mm | 12 x 4 mm | |

| 9 x 3 mm | 12 x 5 mm | |

| 9 x 4 mm | 12 x 5.5 mm | |

| 10 x 3 mm | 13 x 3 mm | |

| 10 x 3.5 mm | 13 x 3.5 mm | |

| 10 x 4 mm | 20x3 mm | |

| 10 x 5 mm | 20x3.5 mm | |

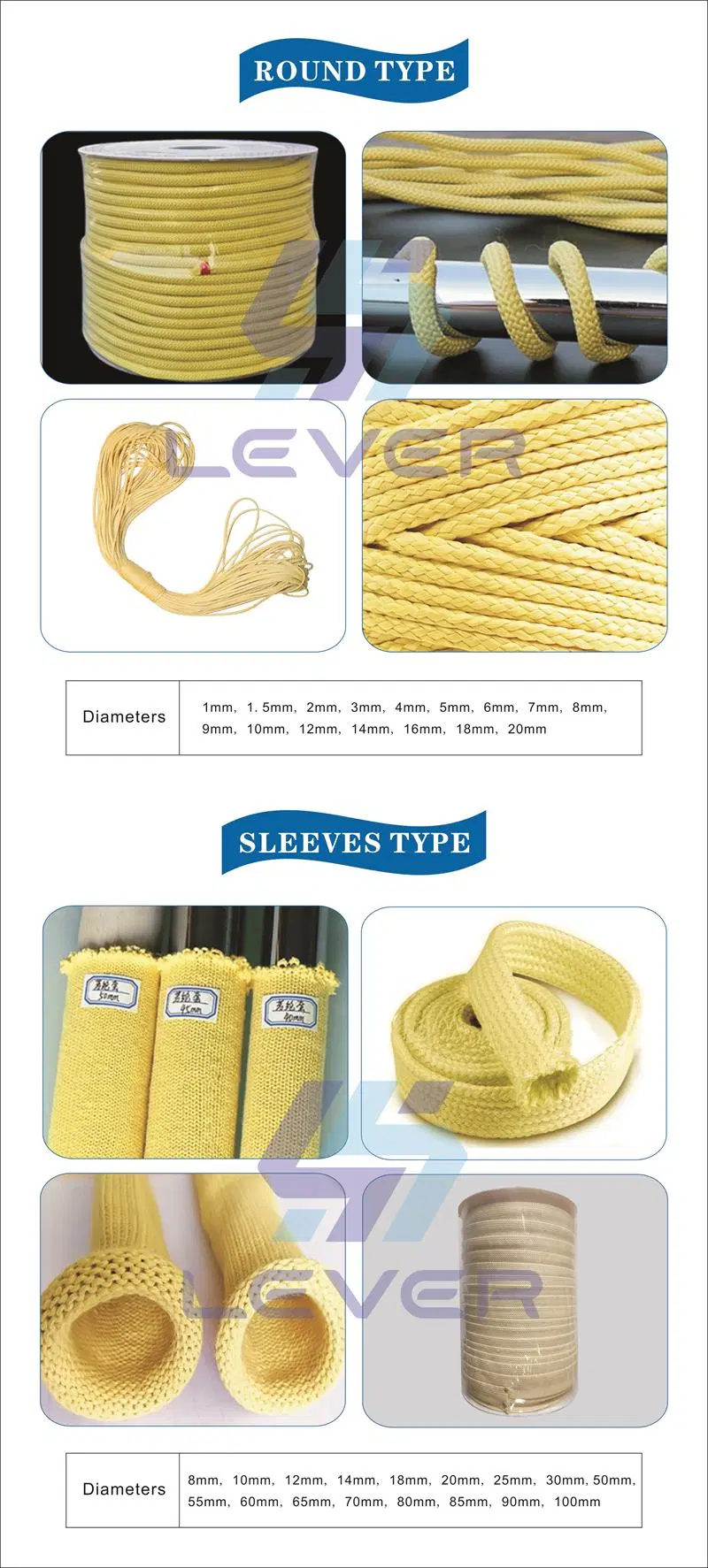

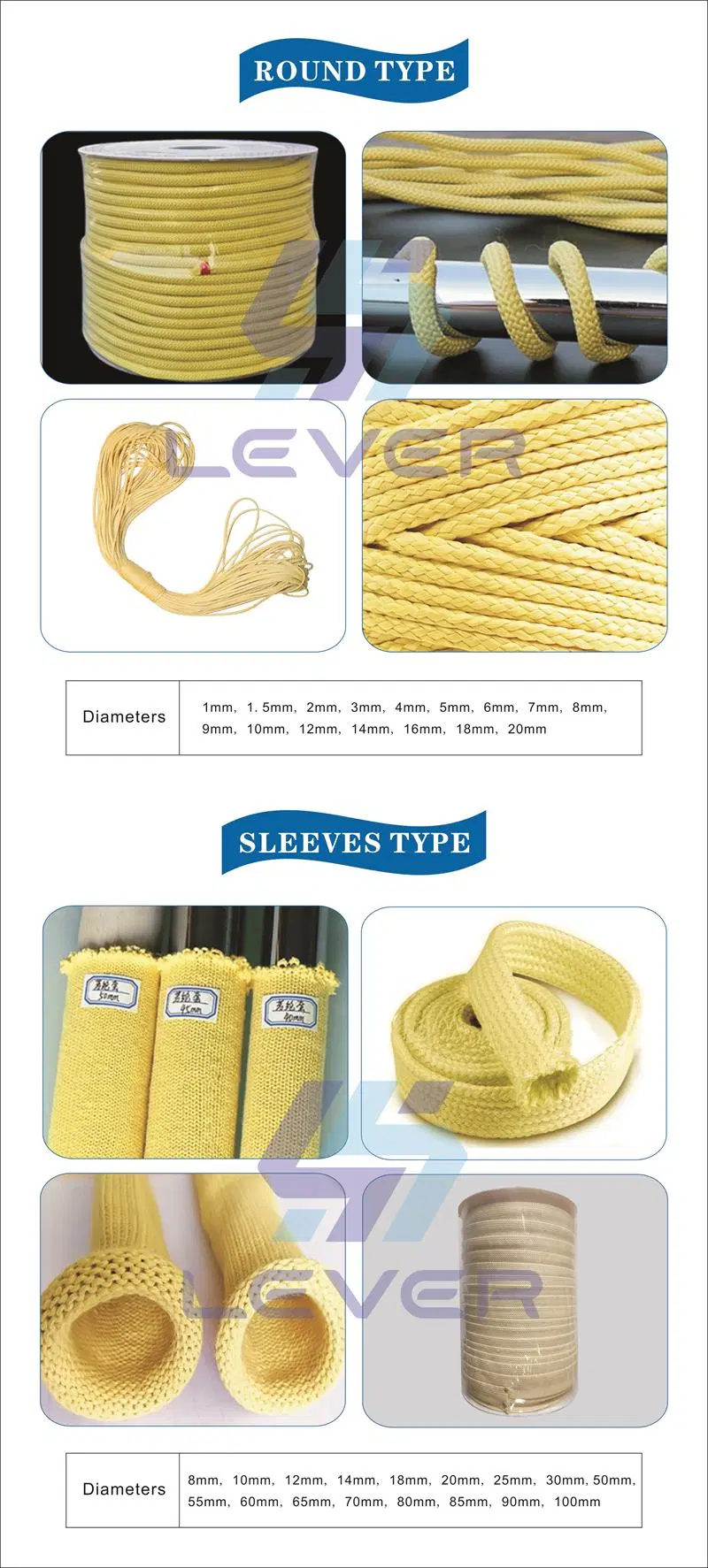

| Square Type Kevlar Aramid Rope | ||

| 4 x 4 mm | 8 x 8 mm | |

| 5 x 5 mm | 10 x 10 mm | |

| 5.5 x 5.5 mm | 12 x 12 mm | |

| 6 x 6 mm | 15 x 15 mm | |

| Round Type Kevlar Aramid Rope | ||

| Diameters | 1mm, 1.5mm, 2mm, 3mm, 4mm, 5mm, 6mm, 7mm, 8mm, 9mm, 10mm, 12mm, 14mm, 16mm, 18mm, 20mm | |

| Kevlar Aramid Sleeve Rope | ||

| Diameters | 8mm, 10mm, 12mm, 14mm, 18mm, 20mm, 25mm, 30mm, 50mm, 55mm, 60mm, 65mm, 70mm, 80mm, 85mm, 90mm, 100mm | |

| Not all specifications listed here, pls contact us for more specifications | ||

Product Show: