Basic Info.

Model NO.

780gsm

The Second Layer

180GSM PP

Suitable Process

Rtm or Infusion

The Third Layer

300GSM

Transport Package

Carton and Pallet

Specification

MNM300/180/300

Trademark

utek

Origin

China

HS Code

7019

Production Capacity

400ton/Month

Product Description

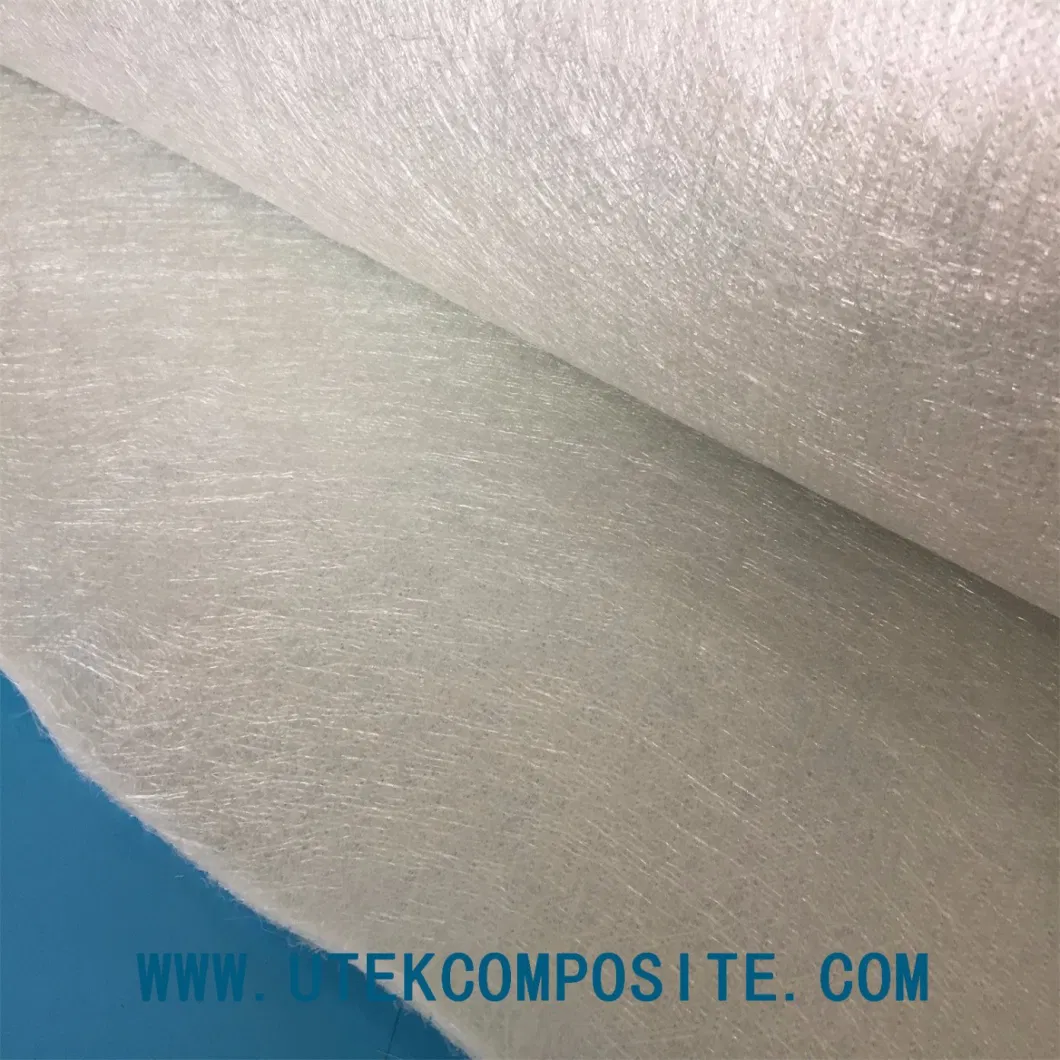

780gsm Fiberglass PP Core Mat is made with polypropylene non-woven core and chopped strand stitched together mechanically, 2 layers of 300gsm chopped strand mat with 180g/m2 PP core, it is used for all the closed mold process needs and helps improve productivity and quality. Easy flow core for rapid wet-out and mold filling.

Properties:

Improved mechanical properties and reduction of weight through an optimal positioning of the glass mat on the outside surfaces of the composite part.

Improved resin flow around PP core, which is not slowed by the glass fiber.

Technical Data:

PP core used:

Packing & Storage:

Each roll covering by polyethylene plastic bag,then placed into carton and set on pallet,or set on pallet directly.

The pallet shall no be higher than 2 layers.

Product shall be placed under dryness condition and shall no be open the covering membrane until applying.

Give us a chance, and we' ll return you with satisfaction.

Properties:

Improved mechanical properties and reduction of weight through an optimal positioning of the glass mat on the outside surfaces of the composite part.

Improved resin flow around PP core, which is not slowed by the glass fiber.

Technical Data:

Product Code | CS (g/m 2 ) | Core (g/m 2 ) | CS (g/m 2 ) | Total Weight (g/m 2 ) |

| M300/P180/M300 | 300 | 180 | 300 | 780 |

| M450/P180/M450 | 450 | 180 | 450 | 1080 |

| M600/P180/M600 | 600 | 180 | 600 | 1380 |

| M300/P180 | 300 | 180 | -- | 480 |

| M450/P250 | 450 | 180 | -- | 630 |

| M600-/P250 | 600 | 180 | -- | 780 |

PP core used:

Packing & Storage:

Each roll covering by polyethylene plastic bag,then placed into carton and set on pallet,or set on pallet directly.

The pallet shall no be higher than 2 layers.

Product shall be placed under dryness condition and shall no be open the covering membrane until applying.

Give us a chance, and we' ll return you with satisfaction.